Page 143 - Modular design for machine tools

P. 143

Engineering Guides and Future Perspectives of Modular Design 103

This idea has later merchandised by Index Co. in 1999, and the

machine named “Vertical Line” was exhibited on the occasion of EMO

Shows in Paris (see Fig. 1-5). As can be readily seen, the successors of

the engine lathe of Ramo make and complex machining center are the

machining complex and processing complex, respectively. For the ease

of understanding, some representative machines will be quickly shown

in the following.

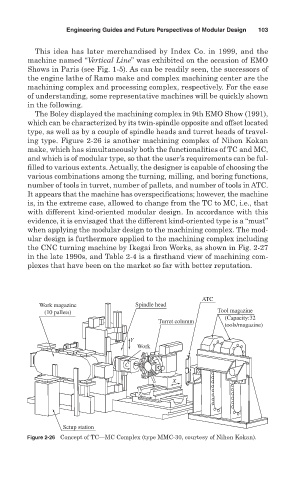

The Boley displayed the machining complex in 9th EMO Show (1991),

which can be characterized by its twin-spindle opposite and offset located

type, as well as by a couple of spindle heads and turret heads of travel-

ing type. Figure 2-26 is another machining complex of Nihon Kokan

make, which has simultaneously both the functionalities of TC and MC,

and which is of modular type, so that the user’s requirements can be ful-

filled to various extents. Actually, the designer is capable of choosing the

various combinations among the turning, milling, and boring functions,

number of tools in turret, number of pallets, and number of tools in ATC.

It appears that the machine has overspecifications; however, the machine

is, in the extreme case, allowed to change from the TC to MC, i.e., that

with different kind-oriented modular design. In accordance with this

evidence, it is envisaged that the different kind-oriented type is a “must”

when applying the modular design to the machining complex. The mod-

ular design is furthermore applied to the machining complex including

the CNC turning machine by Ikegai Iron Works, as shown in Fig. 2-27

in the late 1990s, and Table 2-4 is a firsthand view of machining com-

plexes that have been on the market so far with better reputation.

ATC

Work magazine Spindle head

(10 pallets) Tool magazine

(Capacity:32

Turret columm

tools/magazine)

Y

Work

C

X

Z

Setup station

Figure 2-26 Concept of TC—MC Complex (type MMC-30, courtesy of Nihon Kokan).