Page 112 - Book Hosokawa Nanoparticle Technology Handbook

P. 112

FUNDAMENTALS CH. 2 STRUCTURAL CONTROL OF NANOPARTICLES

The supercritical fluid (SCF) has been applied in particles of ZnO–TiO . This synthesis was carried out

2

wide areas like medicine, foods, and electronic using an apparatus having two reactors connected in

devises. In this section, some examples of trials to series. In the first reactor, ZnO nanoparticles were

prepare the composite materials making use of SCF generated and then they were transferred to the second

are introduced. one to synthesize TiO , which produced ZnO–TiO 2

2

First, the synthesis method of nanoparticles using nanocomposite particles. These nanocomposite parti-

the supercritical fluid is briefly summarized, and then cles did not have core–shell structure but agglomerates

some examples of applications for the structure con- with two kinds of randomly dispersed oxides.

trol of composite particles based on it are introduced, Arai et al. [3] reported the synthesis of Ni/Fe O 4

3

finally referring to the future development for cre- composite particles in the subcritical water as reaction

ation of the composite materials. field using a flow-type synthesis apparatus. This com-

posite particle was formed in two stages. First, the

2.4.3.1 Synthesis of nanoparticles using the

Fe O particles were synthesized hydrothermally as a

3

4

supercritical fluid core and then Ni was deposited onto the Fe O parti-

3

4

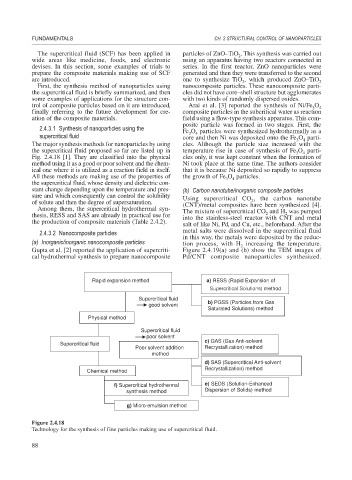

The major synthesis methods for nanoparticles by using cles. Although the particle size increased with the

the supercritical fluid proposed so far are listed up in temperature rise in case of synthesis of Fe O parti-

4

3

Fig. 2.4.18 [1]. They are classified into the physical cles only, it was kept constant when the formation of

method using it as a good or poor solvent and the chem- Ni took place at the same time. The authors consider

ical one where it is utilized as a reaction field in itself. that it is because Ni deposited so rapidly to suppress

All these methods are making use of the properties of the growth of Fe O particles.

4

3

the supercritical fluid, whose density and dielectric con-

stant change depending upon the temperature and pres- (b) Carbon nanotube/inorganic composite particles

sure and which consequently can control the solubility Using supercritical CO , the carbon nanotube

2

of solute and then the degree of supersaturation. (CNT)/metal composites have been synthesized [4].

Among them, the supercritical hydrothermal syn- The mixture of supercritical CO and H was pumped

2

2

thesis, RESS and SAS are already in practical use for into the stainless-steel reactor with CNT and metal

the production of composite materials (Table 2.4.2).

salt of like Ni, Pd, and Cu, etc., beforehand. After the

metal salts were dissolved in the supercritical fluid

2.4.3.2 Nanocomposite particles

in this way, the metals were deposited by the reduc-

(a) Inorganic/inorganic nanocomposite particles tion process, with H increasing the temperature.

2

Gupta et al. [2] reported the application of supercriti- Figure 2.4.19(a) and (b) show the TEM images of

cal hydrothermal synthesis to prepare nanocomposite Pd/CNT composite nanoparticles synthesized.

Rapid expansion method a) RESS (Rapid Expansion of

Supercritical Solutions) method

Supercritical fluid

b) PGSS (Particles from Gas

good solvent

Saturated Solutions) method

Physical method

Supercritical fluid

poor solvent

c) GAS (Gas Anti-solvent

Supercritical fluid

Poor solvent addition Recrystallization) method

method

d) SAS (Supercritical Anti-solvent

Recrystallization) method

Chemical method

f) Supercritical hydrothermal e) SEDS (Solution-Enhanced

synthesis method Dispersion of Solids) method

g) Micro-emulsion method

Figure 2.4.18

Technology for the synthesis of fine particles making use of supercritical fluid.

88