Page 111 - Book Hosokawa Nanoparticle Technology Handbook

P. 111

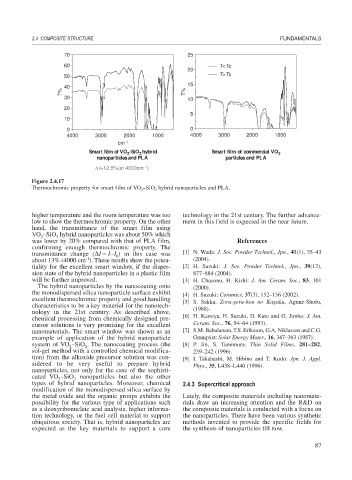

2.4 COMPOSITE STRUCTURE FUNDAMENTALS

70 25

60 T<Tc

20

50 T>Tc

15

40

T% T%

30 10

20

5

10

0 0

4000 3000 2000 1000 4000 3000 2000 1000

cm -1

Smart film of VO -SiO hybrid Smart film of commercial VO 2

2

2

nanoparticles and PLA particles and PLA

-1

ΔI=12.8%(at 4000cm )

Figure 2.4.17

Thermochromic property for smart film of VO –SiO hybrid nanoparticles and PLA.

2

2

higher temperature and the room temperature was too technology in the 21st century. The further advance-

low to show the thermochromic property. On the other ment in this field is expected in the near future.

hand, the transmittance of the smart film using

VO –SiO hybrid nanoparticles was about 50% which

2

2

was lower by 20% compared with that of PLA film, References

confirming enough thermochromic property. The

transmittance change ( I I–I ) in this case was [1] N. Wada: J. Soc. Powder Technol., Jpn., 41(1), 35–43

0

-1

about 13% (4000 cm ). These results show the poten- (2004).

tiality for the excellent smart window, if the disper- [2] H. Suzuki: J. Soc. Powder Technol., Jpn., 39(12),

sion state of the hybrid nanoparticles in a plastic film 877–884 (2004).

will be further improved. [3] H. Chazono, H. Kishi: J. Am. Ceram. Soc., 83, 101

The hybrid nanoparticles by the nanocoating onto (2000).

the monodispersed silica nanoparticle surface exhibit [4] H. Suzuki: Ceramics, 37(3), 152–156 (2002).

excellent thermochromic property and good handling [5] S. Sakka: Zoru-geru-hou no Kagaku, Agune-Shofu,

characteristics to be a key material for the nanotech- (1988).

nology in the 21st century. As described above,

chemical processing from chemically designed pre- [6] H. Kamiya, H. Suzuki, D. Kato and G. Jimbo: J. Am.

cursor solutions is very promising for the excellent Ceram. Soc., 76, 54–64 (1993).

nanomaterials. The smart window was shown as an [7] S.M. Babulanam, T.S. Eriksson, G.A. Niklasson and C.G.

example of application of the hybrid nanoparticle Granqvist: Solar Energy Mater., 16, 347–363 (1987).

system of VO –SiO . The nanocoating process (the [8] P. Jin, S. Tanemura: Thin Solid Films, 281–282,

2

2

sol-gel method with a controlled chemical modifica- 239–242 (1996).

tion) from the alkoxide precursor solution was con- [9] I. Takahashi, M. Hibino and T. Kudo: Jpn. J. Appl.

sidered to be very useful to prepare hybrid Phys., 35, L438–L440 (1996).

nanoparticles, not only for the case of the sophisti-

cated VO –SiO nanoparticles but also the other

2

2

types of hybrid nanoparticles. Moreover, chemical 2.4.3 Supercritical approach

modification of the monodispersed silica surface by

the metal oxide and the organic groups exhibits the Lately, the composite materials including nanomate-

possibility for the various type of applications such rials draw an increasing attention and the R&D on

as a deoxyribonucleic acid analysis, higher informa- the composite materials is conducted with a focus on

tion technology, or the fuel cell material to support the nanoparticles. There have been various synthetic

ubiquitous society. That is, hybrid nanoparticles are methods invented to provide the specific fields for

expected as the key materials to support a core the synthesis of nanoparticles till now.

87