Page 162 - Book Hosokawa Nanoparticle Technology Handbook

P. 162

FUNDAMENTALS CH. 3 CHARACTERISTICS AND BEHAVIOR OF NANOPARTICLES AND ITS DISPERSION SYSTEMS

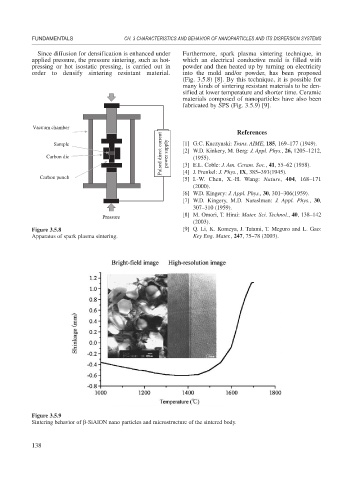

Since diffusion for densification is enhanced under Furthermore, spark plasma sintering technique, in

applied pressure, the pressure sintering, such as hot- which an electrical conductive mold is filled with

pressing or hot isostatic pressing, is carried out in powder and then heated up by turning on electricity

order to densify sintering resistant material. into the mold and/or powder, has been proposed

(Fig. 3.5.8) [8]. By this technique, it is possible for

many kinds of sintering resistant materials to be den-

sified at lower temperature and shorter time. Ceramic

materials composed of nanoparticles have also been

fabricated by SPS (Fig. 3.5.9) [9].

Vacuum chamber References

Pulsed direct current power supply [2] W.D. Kinkery, M. Berg: J. Appl. Phys., 26, 1205–1212,

Sample [1] G.C. Kuczynski: Trans. AIME, 185, 169–177 (1949).

Carbon die [3] E.L. Coble: J. Am. Ceram. Soc., 41, 55–62 (1958).

(1955).

Carbon punch [4] J. Frenkel: J. Phys., IX, 385–391(1945).

[5] I.-W. Chen, X.-H. Wang: Nature, 404, 168–171

(2000).

[6] W.D. Kingery: J. Appl. Phys., 30, 301–306(1959).

[7] W.D. Kingery, M.D. Naraslman: J. Appl. Phys., 30,

307–310 (1959).

[8] M. Omori, T. Hirai: Mater. Sci. Technol., 40, 138–142

Pressure

(2003).

Figure 3.5.8 [9] Q. Li, K. Komeya, J. Tatami, T. Meguro and L. Gao:

Apparatus of spark plasma sintering. Key Eng. Mater., 247, 75–78 (2003).

Figure 3.5.9

Sintering behavior of

-SiAlON nano particles and microstructure of the sintered body.

138