Page 240 - Book Hosokawa Nanoparticle Technology Handbook

P. 240

FUNDAMENTALS CH. 4 CONTROL OF NANOSTRUCTURE OF MATERIALS

methacrylate monomer and palladium or platinum [9] K. Chujo: Nanokonpojitto No Sekai (in Japanese,

acetyl acetate is polymerized and reduced at the same World of Nanocomposite, Kogyo Chosakai Publishing,

time at 60°C to obtain metal nanoparticle/poly methyl Tokyo, p. 161 (2000).

methacrylate composite [16]. Since the polymerization [10] S. Choi, K. Lee and S. Park: Stud. Surf. Sci. Catal.,

of the monomer capable of forming the complex and the 146, 93 (2003).

particle formation reaction proceed at the same time, [11] J. Fang, L.D. Tung, K.L. Stokes, J. He, D. Caruntu,

this process can be defined as one of the Pechini meth- W.L. Zhou and C.J. O’Commor: J. Appl. Phys., 91,

ods, although the esterification reaction does not occur.

In the simultaneous syntheses of polymers and particles 8816 (2002).

(or particle syntheses in polymers), the stability is con- [12] M.S. Pechini: US Patent No. 3, 330, 697 (1967).

sidered important for inorganic compounds as precur- [13] B.L. Cushing, V.L. Kolesnichenko and C.J. O’Connor:

sors of particles and complex compounds to be formed. Chem. Rev., 104(9), 3893 (2004).

In this field, many reports concentrate on acrylic [14] S. Yamamoto, M. Kakihana and S. Kato: J. Alloys

polymer and polyalkylene glycol, the reason being, Compos., 297, 81–86 (2000).

probably, that the stability of the complex is a key [15] P. Duran, F. Capel, D. Gutierrez, J. Tarataj and

issue. Other examples of polymer systems include a C. Moure: J. Euro. Ceram. Soc., 22, 1711–1721 (2002).

study on the preparation of nanocomposites in the [16] Y. Nakao: Kobunshi: High Polymers, Japan, 43,

PET synthesis reaction field [17]. They may be clas- 852–855 (1994).

sified as organic/inorganic hybrid materials rather

than polymer/particle nanocomposites. [17] T. Morimoto, M. Yoshida and K. Okuyama: J. Soc.

Mater. Sci., Jpn., 54, 393–398 (2005).

References

4.4.5 ECAP

[1] The Chemical Society of Japan: Kikan Kagaku

Sosetsu No.42, Organic–Inorganic Hybrid Material, (1) ECAP Process

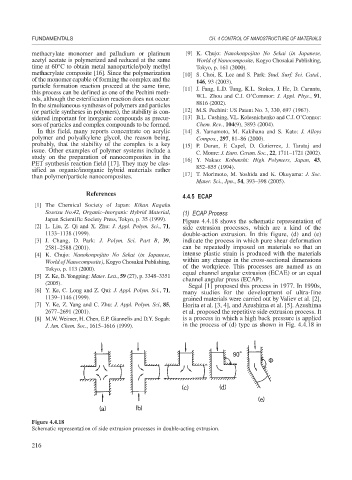

Japan Scientific Society Press, Tokyo, p. 35 (1999). Figure 4.4.18 shows the schematic representation of

[2] L. Liu, Z. Qi and X. Zhu: J. Appl. Polym. Sci., 71, side extrusion processes, which are a kind of the

1133–1138 (1999). double-action extrusion. In this figure, (d) and (e)

[3] J. Chang, D. Park: J. Polym. Sci. Part B, 39, indicate the process in which pure shear deformation

2581–2588 (2001). can be repeatedly imposed on materials so that an

[4] K. Chujo: Nanokonpojitto No Sekai (in Japanese, intense plastic strain is produced with the materials

within any change in the cross-sectional dimensions

World of Nanocomposite), Kogyo Chosakai Publishing,

of the workpiece. This processes are named as an

Tokyo, p. 113 (2000).

equal channel angular extrusion (ECAE) or an equal

[5] Z. Ke, B. Yongping: Mater. Lett., 59 (27), p. 3348–3351

channel angular press (ECAP).

(2005).

Segal [1] proposed this process in 1977. In 1990s,

[6] Y. Ke, C. Long and Z. Qui: J. Appl. Polym. Sci., 71, many studies for the development of ultra-fine

1139–1146 (1999). grained materials were carried out by Valiev et al. [2],

[7] Y. Ke, Z. Yang and C. Zhu: J. Appl. Polym. Sci, 85, Horita et al. [3, 4], and Azushima et al. [5]. Azushima

2677–2691 (2001). et al. proposed the repetitive side extrusion process. It

[8] M.W. Weimer, H. Chen, E.P. Giannelis and D.Y. Sogah: is a process in which a high back pressure is applied

J. Am. Chem. Soc., 1615–1616 (1999). in the process of (d) type as shown in Fig. 4.4.18 in

Figure 4.4.18

Schematic representation of side extrusion processes in double-acting extrusion.

216