Page 358 - Book Hosokawa Nanoparticle Technology Handbook

P. 358

FUNDAMENTALS CH. 6 EVALUATION METHODS FOR PROPERTIES OF NANOSTRUCTURED BODY

grain size, and then, is responsible for the softening phe- [3] I.A. Ovi’dko: Int. J. Mater. Rev., 50, 65–82 (2005).

nomena of nanocrystalline materials in the intermediate [4] T.G. Nieh, J. Wadsworth and O.D. Sherby:

temperature range [1–3]. Fig. 6.2.15 shows that Superplasticity in Metals and Ceramics, Cambridge

nanocrystalline material can be deformed at lower tem- University Press, Cambridge (1997).

peratures. [5] Z.J. Shen, H. Peng and M. Nygren: Adv. Mater., 15,

Ceramics, e.g., oxides, nitrides and carbides, are 1006–1009 (2003).

hard, strong and stiff materials. They are brittle, and [6] B.F. Dyson, R.D. Lohr and R. Morrel (Eds.): Mechanical

lack the ductility of metals at ambient temperatures.

Since the discovery of superplasticity of Y O -stabi- Testing of Engineering Ceramics at High Ttemperatures,

3

2

lized tetragonal ZrO polycrystals (Y-TZP) [10], the Elsevier Applied Science, London (1989).

2

research on superplasticity has further expanded to [7] F. Wakai, H. Kato: Adv. Ceram. Mater., 3, 71–76 (1988).

various oxides and non-oxides [11]. A remarkably [8] M. Yoshida, et al.: J. Am. Ceram. Soc., 85, 2834–2836

high elongation of 2,510% has been achieved at high- (2002).

strain rate in ZrO -based composites [12]. [9] M. Jiménez-Melendo, et al.: J. Am. Ceram. Soc., 81,

2

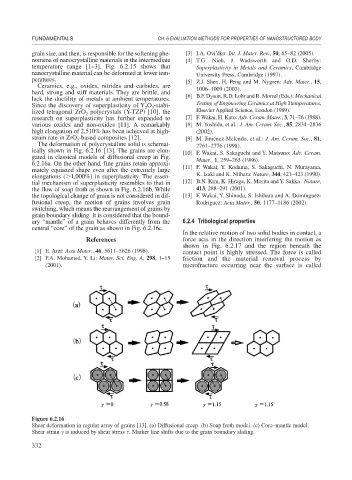

The deformation of polycrystalline solid is schemat- 2761–2776 (1998).

ically shown in Fig. 6.2.16 [13]. The grains are elon- [10] F. Wakai, S. Sakaguchi and Y. Matsuno: Adv. Ceram.

gated in classical models of diffusional creep in Fig. Mater., 1, 259–263 (1986).

6.2.16a. On the other hand, fine grains retain approxi- [11] F. Wakai, Y. Kodama, S. Sakaguchi, N. Murayama,

mately equiaxed shape even after the extremely large

elongations ( 1,000%) in superplasticity. The essen- K. Izaki and K. Niihara: Nature, 344, 421–423 (1990).

tial mechanism of superplasticity resembles to that in [12] B.N. Kim, K. Hiraga, K. Morita and Y. Sakka : Nature,

the flow of soap froth as shown in Fig. 6.2.16b. While 413, 288–291 (2001).

the topological change of grain is not considered in dif- [13] F. Wakai, Y. Shinoda, S. Ishihara and A. Domínguez-

fusional creep, the motion of grains involves grain Rodríguez: Acta Mater., 50, 1177–1186 (2002).

switching, which means the rearrangement of grains by

grain boundary sliding. It is considered that the bound-

ary “mantle” of a grain behaves differently from the 6.2.4 Tribological properties

central “core” of the grain as shown in Fig. 6.2.16c.

In the relative motion of two solid bodies in contact, a

References force acts in the direction interfering the motion as

shown in Fig. 6.2.17 and the region beneath the

[1] E. Arzt: Acta Mater., 46, 5611–5626 (1998). contact point is highly stressed. The force is called

[2] F.A. Mohamed, Y. Li: Mater. Sci. Eng. A, 298, 1–15 friction and the material removal process by

(2001). microfracture occurring near the surface is called

Figure 6.2.16

Shear deformation in regular array of grains [13]. (a) Diffusional creep. (b) Soap froth model. (c) Core–mantle model.

Shear strain

is induced by shear stress . Marker line shifts due to the grain boundary sliding.

332