Page 47 - Book Hosokawa Nanoparticle Technology Handbook

P. 47

FUNDAMENTALS CH. 1 BASIC PROPERTIES AND MEASURING METHODS OF NANOPARTICLES

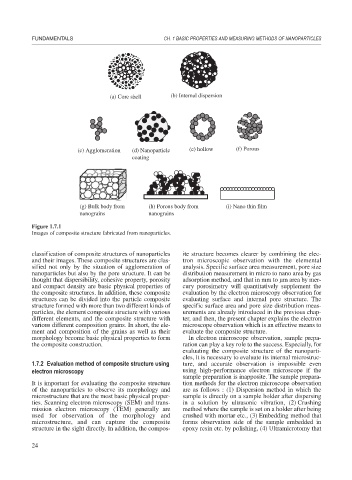

(a) Core shell (b) Internal dispersion

(c) Agglomeration (d) Nanoparticle (e) hollow (f) Porous

coating

(g) Bulk body from (h) Porous body from (i) Nano thin film

nanograins nanograins

Figure 1.7.1

Images of composite structure fabricated from nanoparticles.

classification of composite structures of nanoparticles ite structure becomes clearer by combining the elec-

and their images. These composite structures are clas- tron microscopic observation with the elemental

sified not only by the situation of agglomeration of analysis. Specific surface area measurement, pore size

nanoparticles but also by the pore structure. It can be distribution measurement in micro to nano area by gas

thought that dispersibility, cohesive property, porosity adsorption method, and that in mm to m area by mer-

and compact density are basic physical properties of cury porosimetry will quantitatively supplement the

the composite structures. In addition, these composite evaluation by the electron microscopy observation for

structures can be divided into the particle composite evaluating surface and internal pore structure. The

structure formed with more than two different kinds of specific surface area and pore size distribution meas-

particles, the element composite structure with various urements are already introduced in the previous chap-

different elements, and the composite structure with ter, and then, the present chapter explains the electron

various different composition grains. In short, the ele- microscope observation which is an effective means to

ment and composition of the grains as well as their evaluate the composite structure.

morphology become basic physical properties to form In electron microscope observation, sample prepa-

the composite construction. ration can play a key role to the success. Especially, for

evaluating the composite structure of the nanoparti-

cles, it is necessary to evaluate its internal microstruc-

1.7.2 Evaluation method of composite structure using ture, and accurate observation is impossible even

electron microscopy using high-performance electron microscope if the

sample preparation is inapposite. The sample prepara-

It is important for evaluating the composite structure tion methods for the electron microscope observation

of the nanoparticles to observe its morphology and are as follows : (1) Dispersion method in which the

microstructure that are the most basic physical proper- sample is directly on a sample holder after dispersing

ties. Scanning electron microscopy (SEM) and trans- in a solution by ultrasonic vibration, (2) Crushing

mission electron microscopy (TEM) generally are method where the sample is set on a holder after being

used for observation of the morphology and crushed with mortar etc., (3) Embedding method that

microstructure, and can capture the composite forms observation side of the sample embedded in

structure in the sight directly. In addition, the compos- epoxy resin etc. by polishing, (4) Ultramicrotomy that

24