Page 519 - Book Hosokawa Nanoparticle Technology Handbook

P. 519

18 DEVELOPMENT OF HIGH-PERFORMANCE ELECTROCHEMICAL REACTORS APPLICATIONS

20mm*0.5

15mm

Solid electrolyte Catalytic electrode

(oxygen ionic Cathode

conductor) Anode

exhaust gas clean air

Catalytic

electrode

Cathode

Solid Oxygen pumping

nano redox-reaction zone

electrolyte

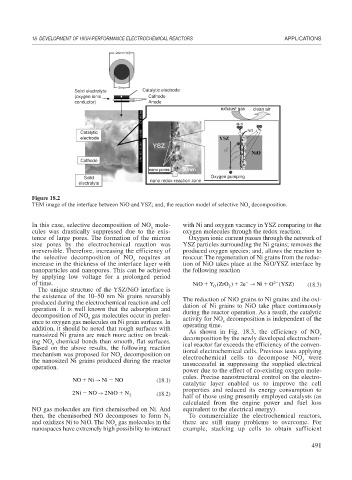

Figure 18.2

TEM image of the interface between NiO and YSZ; and, the reaction model of selective NO decomposition.

x

In this case, selective decomposition of NO mole- with Ni and oxygen vacancy in YSZ comparing to the

x

cules was drastically suppressed due to the exis- oxygen molecules through the redox reaction.

tence of large pores. The formation of the micron Oxygen ionic current passes through the network of

size pores by the electrochemical reaction was YSZ particles surrounding the Ni grains; removes the

irreversible. Therefore, increasing the efficiency of produced oxygen species; and, allows the reaction to

the selective decomposition of NO requires an reoccur. The regeneration of Ni grains from the reduc-

x

increase in the thickness of the interface layer with tion of NiO takes place at the NiO/YSZ interface by

nanoparticles and nanopores. This can be achieved the following reaction

by applying low voltage for a prolonged period

2

of time. NiO Y ZrO 2 e Ni O ( YSZ) (18.3)

)

(

2

O

The unique structure of the YSZ/NiO interface is

the existence of the 10–50 nm Ni grains reversibly The reduction of NiO grains to Ni grains and the oxi-

produced during the electrochemical reaction and cell dation of Ni grains to NiO take place continuously

operation. It is well known that the adsorption and during the reactor operation. As a result, the catalytic

decomposition of NO gas molecules occur in prefer- activity for NO decomposition is independent of the

x

ence to oxygen gas molecules on Ni grain surfaces. In operating time. x

addition, it should be noted that rough surfaces with As shown in Fig. 18.3, the efficiency of NO

nanosized Ni grains are much more active on break- decomposition by the newly developed electrochem- x

ing NO chemical bonds than smooth, flat surfaces. ical reactor far exceeds the efficiency of the conven-

x

Based on the above results, the following reaction tional electrochemical cells. Previous tests applying

mechanism was proposed for NO decomposition on electrochemical cells to decompose NO were

x

the nanosized Ni grains produced during the reactor unsuccessful in suppressing the supplied electrical

x

operation.

power due to the effect of co-existing oxygen mole-

NO Ni Ni NO (18.1) cules. Precise nanostructural control on the electro-

catalytic layer enabled us to improve the cell

2Ni NO 2NiO N 2 (18.2) properties and reduced its energy consumption to

half of those using presently employed catalysts (as

calculated from the engine power and fuel loss

NO gas molecules are first chemisorbed on Ni. And equivalent to the electrical energy).

then, the chemisorbed NO decomposes to form N 2 To commercialize the electrochemical reactors,

and oxidizes Ni to NiO. The NO gas molecules in the there are still many problems to overcome. For

x

nanospaces have extremely high possibility to interact example, stacking up cells to obtain sufficient

491