Page 521 - Book Hosokawa Nanoparticle Technology Handbook

P. 521

18 DEVELOPMENT OF HIGH-PERFORMANCE ELECTROCHEMICAL REACTORS APPLICATIONS

Catho de : 2NO + 4e - - N 2 2 + 2 O 2- 2-

N + 2O

Cathode : 2NO + 4e

2NO N2

Ag

Cathode 2e - CGO + NiO

Electrolyte

2O 2- CGO

Anode 2e - Ag

CGO + Ag

graphite

CO 2

CO

Anode : C + 2O

+ 4e

A nod e : C + 2O 2- 2- CO + 4e - -

2 2

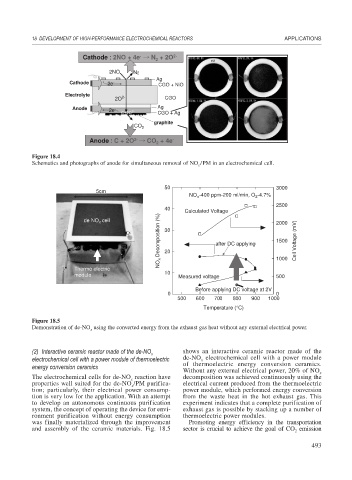

Figure 18.4

Schematics and photographs of anode for simultaneous removal of NO /PM in an electrochemical cell.

x

50 3000

5cm

NO -400 ppm-200 ml/min, O -4.7%

x

2

2500

40 Calculated Voltage

NO x Decomposition (%) 20 after DC applying 1500 Cell Voltage (mV)

de NO cell 30 2000

x

Thermo electric 1000

module 10 Measured voltage 500

Before applying DC voltage at 2V

0 0

500 600 700 800 900 1000

Temperature (°C)

Figure 18.5

Demonstration of de-NO using the converted energy from the exhaust gas heat without any external electrical power.

x

(2) Interactive ceramic reactor made of the de-NO shows an interactive ceramic reactor made of the

x

electrochemical cell with a power module of thermoelectric de-NO electrochemical cell with a power module

x

of thermoelectric energy conversion ceramics.

energy conversion ceramics

Without any external electrical power, 20% of NO x

The electrochemical cells for de-NO reaction have decomposition was achieved continuously using the

x

properties well suited for the de-NO /PM purifica- electrical current produced from the thermoelectric

x

tion; particularly, their electrical power consump- power module, which performed energy conversion

tion is very low for the application. With an attempt from the waste heat in the hot exhaust gas. This

to develop an autonomous continuous purification experiment indicates that a complete purification of

system, the concept of operating the device for envi- exhaust gas is possible by stacking up a number of

ronment purification without energy consumption thermoelectric power modules.

was finally materialized through the improvement Promoting energy efficiency in the transportation

and assembly of the ceramic materials. Fig. 18.5 sector is crucial to achieve the goal of CO emission

2

493