Page 111 - Nanotechnology an introduction

P. 111

electrical current density more than 1000 times greater than metals such as silver and copper. Conductance is ballistic; i.e., electrons can pass

through the nanotube without heating it. If n − m = 3, then the nanotube is semiconducting. Otherwise the nanotube is a moderate semiconductor.

The three methods for producing carbon nanotubes are the laser furnace, the carbon arc (i.e., vaporizing graphitic electrodes), and (plasma-

enhanced) chemical vapor deposition (Figure 9.4 and Figure 9.5). The latter has turned out to be the best for large-scale production of relatively

pure material. Carbon nanotubes are often closed at one or both ends by a hemisphere of fullerene.

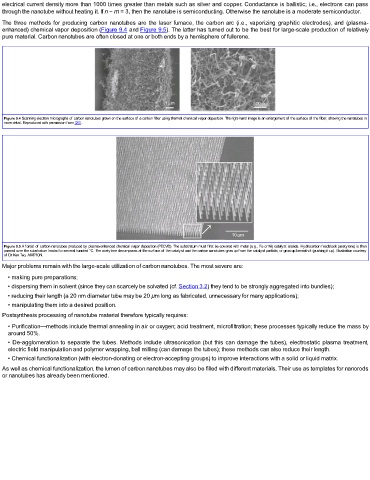

Figure 9.4 Scanning electron micrographs of carbon nanotubes grown on the surface of a carbon fiber using thermal chemical vapor deposition. The right-hand image is an enlargement of the surface of the fiber, showing the nanotubes in

more detail. Reproduced with permission from [24].

Figure 9.5 A forest of carbon nanotubes produced by plasma-enhanced chemical vapor deposition (PECVD). The substratum must first be covered with metal (e.g., Fe or Ni) catalyst islands. Hydrocarbon feedstock (acetylene) is then

passed over the substratum heated to several hundred °C. The acetylene decomposes at the surface of the catalyst and the carbon nanotubes grow up from the catalyst particle, or grow up beneath it (pushing it up). Illustration courtesy

of Dr Ken Teo, AIXTRON.

Major problems remain with the large-scale utilization of carbon nanotubes. The most severe are:

• making pure preparations;

• dispersing them in solvent (since they can scarcely be solvated (cf. Section 3.2) they tend to be strongly aggregated into bundles);

• reducing their length (a 20 nm diameter tube may be 20 μm long as fabricated, unnecessary for many applications);

• manipulating them into a desired position.

Postsynthesis processing of nanotube material therefore typically requires:

• Purification—methods include thermal annealing in air or oxygen; acid treatment, microfiltration; these processes typically reduce the mass by

around 50%.

• De-agglomeration to separate the tubes. Methods include ultrasonication (but this can damage the tubes), electrostatic plasma treatment,

electric field manipulation and polymer wrapping, ball milling (can damage the tubes); these methods can also reduce their length.

• Chemical functionalization (with electron-donating or electron-accepting groups) to improve interactions with a solid or liquid matrix.

As well as chemical functionalization, the lumen of carbon nanotubes may also be filled with different materials. Their use as templates for nanorods

or nanotubes has already been mentioned.