Page 93 - New Trends in Eco efficient and Recycled Concrete

P. 93

0%

10%

1 20%

30%

0%

20%

2 60% 40%

80%

0%

30%

3 70% 50%

0%

30%

4 50%

70%

0%

Reference 6 50% 0%

50%

5

0%

50%

7

0%

20%

8 60% 40%

100% 80% 0%

10%

9 20%

30%

0%

10%

10 20%

30%

0 20 40 60 80 100

(A) Compressive strength (MPa)

0%

25%

1 50%

75%

0%

25%

2 50%

75%

0%

3 50% 25%

75%

0%

5%

4 10%

20% 15% 0%

10%

30%

5 100% 70% 50%

Reference 6 100% 70% 0% 30% 0%

10%

50%

7 50% 25%

75%

0%

5%

8 15%

45% 30%

0%

9 20% 10%

50%

0%

60%

10 100%

0%

10%

15%

11 20%

30%

0 20 40 60

(B) Compressive strength (MPa)

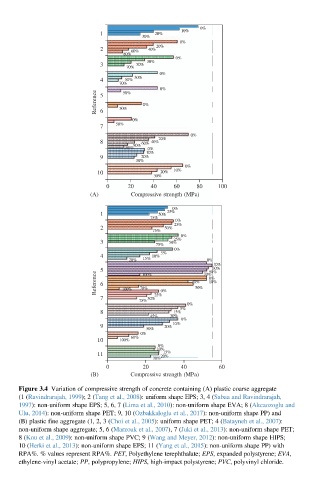

Figure 3.4 Variation of compressive strength of concrete containing (A) plastic coarse aggregate

(1 (Ravindrarajah, 1999); 2 (Tang et al., 2008): uniform shape EPS; 3, 4 (Sabaa and Ravindrarajah,

1997): non-uniform shape EPS; 5, 6, 7 (Lima et al., 2010): non-uniform shape EVA; 8 (Akcaozoglu and

Ulu, 2014): non-uniform shape PET; 9, 10 (Ozbakkaloglu et al., 2017): non-uniform shape PP) and

(B) plastic fine aggregate (1, 2, 3 (Choi et al., 2005): uniform shape PET; 4 (Batayneh et al., 2007):

non-uniform shape aggregate; 5, 6 (Marzouk et al., 2007), 7 (Juki et al., 2013): non-uniform shape PET;

8(Kou et al., 2009): non-uniform shape PVC; 9 (Wang and Meyer, 2012): non-uniform shape HIPS;

10 (Herki et al., 2013): non-uniform shape EPS; 11 (Yang et al., 2015): non-uniform shape PP) with

RPA%. % values represent RPA%. PET, Polyethylene terephthalate; EPS, expanded polystyrene; EVA,

ethylene-vinyl acetate; PP, polypropylene; HIPS, high-impact polystyrene; PVC, polyvinyl chloride.