Page 99 - New Trends in Eco efficient and Recycled Concrete

P. 99

Recycled plastic 73

0%

0.1%

1 0.2%

0.3%

0%

0.1%

2 0.2%

0.3%

0%

0.1%

3 0.2%

0.3%

0% 0.1%

Reference 0% 0.3%

4

0.035%

5

0.065%

0.1%

0%

6 0.2%

0.3%

0.5%

0%

0.2%

7 0.3%

0.5%

0%

0.28%

8

0.56%

1%

0 2 4 6 8 10 12

Splitting tensile strength (MPa)

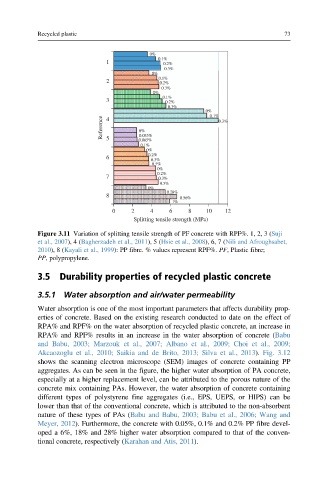

Figure 3.11 Variation of splitting tensile strength of PF concrete with RPF%. 1, 2, 3 (Suji

et al., 2007), 4 (Bagherzadeh et al., 2011), 5 (Hsie et al., 2008), 6, 7 (Nili and Afroughsabet,

2010), 8 (Kayali et al., 1999): PP fibre. % values represent RPF%. PF, Plastic fibre;

PP, polypropylene.

3.5 Durability properties of recycled plastic concrete

3.5.1 Water absorption and air/water permeability

Water absorption is one of the most important parameters that affects durability prop-

erties of concrete. Based on the existing research conducted to date on the effect of

RPA% and RPF% on the water absorption of recycled plastic concrete, an increase in

RPA% and RPF% results in an increase in the water absorption of concrete (Babu

and Babu, 2003; Marzouk et al., 2007; Albano et al., 2009; Choi et al., 2009;

Akcaozoglu et al., 2010; Saikia and de Brito, 2013; Silva et al., 2013). Fig. 3.12

shows the scanning electron microscope (SEM) images of concrete containing PP

aggregates. As can be seen in the figure, the higher water absorption of PA concrete,

especially at a higher replacement level, can be attributed to the porous nature of the

concrete mix containing PAs. However, the water absorption of concrete containing

different types of polystyrene fine aggregates (i.e., EPS, UEPS, or HIPS) can be

lower than that of the conventional concrete, which is attributed to the non-absorbent

nature of these types of PAs (Babu and Babu, 2003; Babu et al., 2006; Wang and

Meyer, 2012). Furthermore, the concrete with 0.05%, 0.1% and 0.2% PP fibre devel-

oped a 6%, 18% and 28% higher water absorption compared to that of the conven-

tional concrete, respectively (Karahan and Atis, 2011).