Page 329 - Numerical Analysis and Modelling in Geomechanics

P. 329

310 ANALYSIS AND DESIGN OF PILE GROUPS

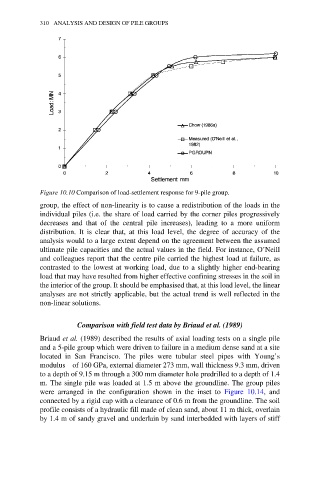

Figure 10.10 Comparison of load-settlement response for 9-pile group.

group, the effect of non-linearity is to cause a redistribution of the loads in the

individual piles (i.e. the share of load carried by the corner piles progressively

decreases and that of the central pile increases), leading to a more uniform

distribution. It is clear that, at this load level, the degree of accuracy of the

analysis would to a large extent depend on the agreement between the assumed

ultimate pile capacities and the actual values in the field. For instance, O’Neill

and colleagues report that the centre pile carried the highest load at failure, as

contrasted to the lowest at working load, due to a slightly higher end-bearing

load that may have resulted from higher effective confining stresses in the soil in

the interior of the group. It should be emphasised that, at this load level, the linear

analyses are not strictly applicable, but the actual trend is well reflected in the

non-linear solutions.

Comparison with field test data by Briaud et al. (1989)

Briaud et al. (1989) described the results of axial loading tests on a single pile

and a 5-pile group which were driven to failure in a medium dense sand at a site

located in San Francisco. The piles were tubular steel pipes with Young’s

modulus of 160 GPa, external diameter 273 mm, wall thickness 9.3 mm, driven

to a depth of 9.15 m through a 300 mm diameter hole predrilled to a depth of 1.4

m. The single pile was loaded at 1.5 m above the groundline. The group piles

were arranged in the configuration shown in the inset to Figure 10.14, and

connected by a rigid cap with a clearance of 0.6 m from the groundline. The soil

profile consists of a hydraulic fill made of clean sand, about 11 m thick, overlain

by 1.4 m of sandy gravel and underlain by sand interbedded with layers of stiff