Page 348 - Optical Communications Essentials

P. 348

Manufacturing Issues

338 Chapter Twenty

Sintered glass SiO 2 powder (soot)

Reactant

gases Exhaust

Fused silica tube

Moving torch

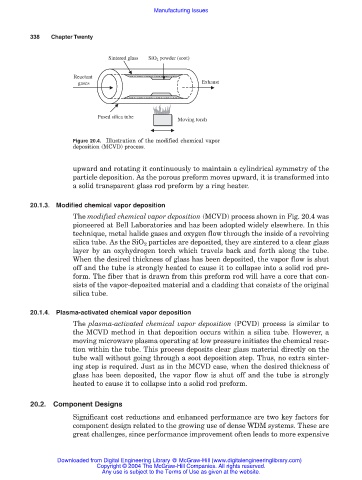

Figure 20.4. Illustration of the modified chemical vapor

deposition (MCVD) process.

upward and rotating it continuously to maintain a cylindrical symmetry of the

particle deposition. As the porous preform moves upward, it is transformed into

a solid transparent glass rod preform by a ring heater.

20.1.3. Modified chemical vapor deposition

The modified chemical vapor deposition (MCVD) process shown in Fig. 20.4 was

pioneered at Bell Laboratories and has been adopted widely elsewhere. In this

technique, metal halide gases and oxygen flow through the inside of a revolving

silica tube. As the SiO 2 particles are deposited, they are sintered to a clear glass

layer by an oxyhydrogen torch which travels back and forth along the tube.

When the desired thickness of glass has been deposited, the vapor flow is shut

off and the tube is strongly heated to cause it to collapse into a solid rod pre-

form. The fiber that is drawn from this preform rod will have a core that con-

sists of the vapor-deposited material and a cladding that consists of the original

silica tube.

20.1.4. Plasma-activated chemical vapor deposition

The plasma-activated chemical vapor deposition (PCVD) process is similar to

the MCVD method in that deposition occurs within a silica tube. However, a

moving microwave plasma operating at low pressure initiates the chemical reac-

tion within the tube. This process deposits clear glass material directly on the

tube wall without going through a soot deposition step. Thus, no extra sinter-

ing step is required. Just as in the MCVD case, when the desired thickness of

glass has been deposited, the vapor flow is shut off and the tube is strongly

heated to cause it to collapse into a solid rod preform.

20.2. Component Designs

Significant cost reductions and enhanced performance are two key factors for

component design related to the growing use of dense WDM systems. These are

great challenges, since performance improvement often leads to more expensive

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.