Page 268 - Optofluidics Fundamentals, Devices, and Applications

P. 268

242 Cha pte r T e n

Dye laser

light Pump laser

z light

y

Top x

mirror

Dye 1 mm 20 μm

flow

Fluid channel

Bottom Fluid in

mirror Light out

(a)

Pump light

Resonator

Outlet

PDMS

(waveguide)

chip Light out

Inlet Bragg grating Microfluidic channel Waveguides Fluid out

Dye solution Laser output 1 cm

(c) (b)

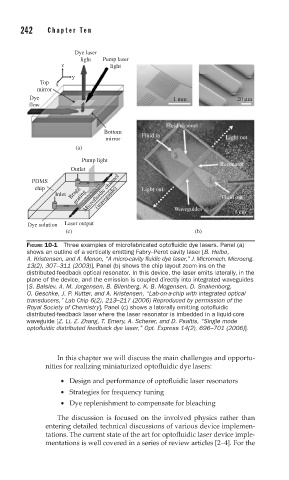

FIGURE 10-1 Three examples of microfabricated optofluidic dye lasers. Panel (a)

shows an outline of a vertically emitting Fabry–Perot cavity laser [B. Helbo,

A. Kristensen, and A. Menon, “A micro-cavity fluidic dye laser,” J. Micromech. Microeng.

13(2), 307–311 (2003)]. Panel (b) shows the chip layout zoom-ins on the

distributed-feedback optical resonator. In this device, the laser emits laterally, in the

plane of the device, and the emission is coupled directly into integrated waveguides

[S. Balslev, A. M. Jorgensen, B. Bilenberg, K. B. Mogensen, D. Snakenborg,

O. Geschke, J. P. Kutter, and A. Kristensen, “Lab-on-a-chip with integrated optical

transducers,” Lab Chip 6(2), 213–217 (2006) Reproduced by permission of the

Royal Society of Chemistry]. Panel (c) shows a laterally emitting optofluidic

distributed-feedback laser where the laser resonator is imbedded in a liquid-core

waveguide [Z. Li, Z. Zhang, T. Emery, A. Scherer, and D. Psaltis, “Single mode

optofluidic distributed feedback dye laser,” Opt. Express 14(2), 696–701 (2006)].

In this chapter we will discuss the main challenges and opportu-

nities for realizing miniaturized optofluidic dye lasers:

• Design and performance of optofluidic laser resonators

• Strategies for frequency tuning

• Dye replenishment to compensate for bleaching

The discussion is focused on the involved physics rather than

entering detailed technical discussions of various device implemen-

tations. The current state of the art for optofluidic laser device imple-

mentations is well covered in a series of review articles [2–4]. For the