Page 289 - Optofluidics Fundamentals, Devices, and Applications

P. 289

Optofluidic Micr oscope 263

Specimen

Illumination

PDMS

channel

Apertures

CMOS

Al layer Flow (b) OFM imaging

(a)

Channel Cross

Y v <50%

X correlation

Screen out

Specimen >50%

>50%

1 μm

L = 9.9 μm Automatic

ΔX θ measurement

δY = 500 nm

(c) (d)

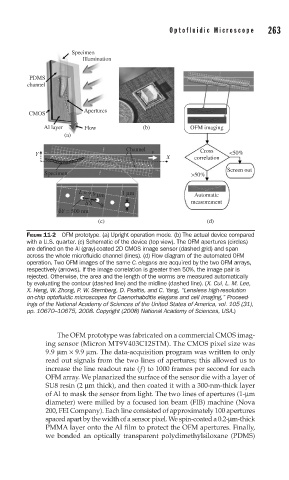

FIGURE 11-2 OFM prototype. (a) Upright operation mode. (b) The actual device compared

with a U.S. quarter. (c) Schematic of the device (top view). The OFM apertures (circles)

are defi ned on the Al (gray)-coated 2D CMOS image sensor (dashed grid) and span

across the whole microfl uidic channel (lines). (d) Flow diagram of the automated OFM

operation. Two OFM images of the same C. elegans are acquired by the two OFM arrays,

respectively (arrows). If the image correlation is greater then 50%, the image pair is

rejected. Otherwise, the area and the length of the worms are measured automatically

by evaluating the contour (dashed line) and the midline (dashed line). (X. Cui, L. M. Lee,

X. Heng, W. Zhong, P. W. Sternberg, D. Psaltis, and C. Yang, “Lensless high-resolution

on-chip optofl uidic microscopes for Caenorhabditis elegans and cell imaging,” Proceed-

ings of the National Academy of Sciences of the United States of America, vol. 105 (31),

pp. 10670–10675, 2008. Copyright (2008) National Academy of Sciences, USA.)

The OFM prototype was fabricated on a commercial CMOS imag-

ing sensor (Micron MT9V403C12STM). The CMOS pixel size was

9.9 μm × 9.9 μm. The data-acquisition program was written to only

read out signals from the two lines of apertures; this allowed us to

increase the line readout rate ( f) to 1000 frames per second for each

OFM array. We planarized the surface of the sensor die with a layer of

SU8 resin (2 μm thick), and then coated it with a 300-nm-thick layer

of Al to mask the sensor from light. The two lines of apertures (1-μm

diameter) were milled by a focused ion beam (FIB) machine (Nova

200, FEI Company). Each line consisted of approximately 100 apertures

spaced apart by the width of a sensor pixel. We spin-coated a 0.2-μm-thick

PMMA layer onto the Al film to protect the OFM apertures. Finally,

we bonded an optically transparent polydimethylsiloxane (PDMS)