Page 294 - Organic Electronics in Sensors and Biotechnology

P. 294

Organic Semiconductor Lasers as Integrated Light Sources for Optical Sensors 271

Laser material Laser material

Laser material

Substrate Substrate Substrate

FIGURE 7.4 Different methods to pattern the active material layer of an

organic semiconductor laser.

Patterning of the substrate might be advantageous since this pro-

cess is independent of the properties of the active material. Hence,

most fabrication techniques for organic semiconductor lasers are

based on structured substrates.

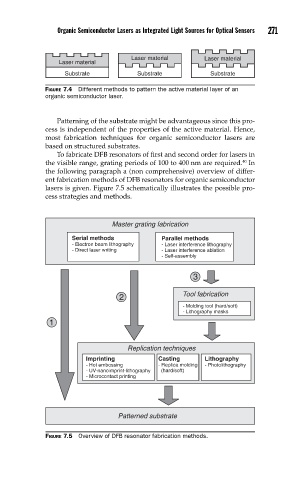

To fabricate DFB resonators of first and second order for lasers in

40

the visible range, grating periods of 100 to 400 nm are required. In

the following paragraph a (non comprehensive) overview of differ-

ent fabrication methods of DFB resonators for organic semiconductor

lasers is given. Figure 7.5 schematically illustrates the possible pro-

cess strategies and methods.

Master grating fabrication

Serial methods Parallel methods

- Electron beam lithography - Laser interference lithography

- Direct laser writing - Laser interference ablation

- Self-assembly

3

2 Tool fabrication

- Molding tool (hard/soft)

- Lithography masks

1

Replication techniques

Imprinting Casting Lithography

- Hot embossing - Replica molding - Photolithography

- UV-nanoimprint-lithography (hard/soft)

- Microcontact printing

Patterned substrate

FIGURE 7.5 Overview of DFB resonator fabrication methods.