Page 298 - Organic Electronics in Sensors and Biotechnology

P. 298

Organic Semiconductor Lasers as Integrated Light Sources for Optical Sensors 275

Laser

α Photoresist Substrate

Sample

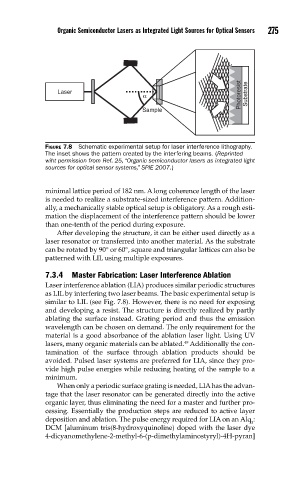

FIGURE 7.8 Schematic experimental setup for laser interference lithography.

The inset shows the pattern created by the interfering beams. (Reprinted

wiht permission from Ref. 25, “Organic semiconductor lasers as integrated light

sources for optical sensor systems,” SPIE 2007.)

minimal lattice period of 182 nm. A long coherence length of the laser

is needed to realize a substrate-sized interference pattern. Addition-

ally, a mechanically stable optical setup is obligatory. As a rough esti-

mation the displacement of the interference pattern should be lower

than one-tenth of the period during exposure.

After developing the structure, it can be either used directly as a

laser resonator or transferred into another material. As the substrate

can be rotated by 90° or 60°, square and triangular lattices can also be

patterned with LIL using multiple exposures.

7.3.4 Master Fabrication: Laser Interference Ablation

Laser interference ablation (LIA) produces similar periodic structures

as LIL by interfering two laser beams. The basic experimental setup is

similar to LIL (see Fig. 7.8). However, there is no need for exposing

and developing a resist. The structure is directly realized by partly

ablating the surface instead. Grating period and thus the emission

wavelength can be chosen on demand. The only requirement for the

material is a good absorbance of the ablation laser light. Using UV

lasers, many organic materials can be ablated. Additionally the con-

49

tamination of the surface through ablation products should be

avoided. Pulsed laser systems are preferred for LIA, since they pro-

vide high pulse energies while reducing heating of the sample to a

minimum.

When only a periodic surface grating is needed, LIA has the advan-

tage that the laser resonator can be generated directly into the active

organic layer, thus eliminating the need for a master and further pro-

cessing. Essentially the production steps are reduced to active layer

deposition and ablation. The pulse energy required for LIA on an Alq :

3

DCM [aluminum tris(8-hydroxyquinoline) doped with the laser dye

4-dicyanomethylene-2-methyl-6-(p-dimethylaminostyryl)-4H-pyran]