Page 299 - Organic Electronics in Sensors and Biotechnology

P. 299

276 Chapter Seven

film is about 10 mJ/cm² using a frequency triple Nd:YAG laser emit-

50

ting 150 ps pulses at 355 nm.

7.3.5 Replication: Imprint Techniques

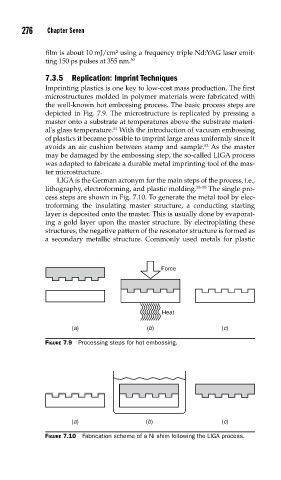

Imprinting plastics is one key to low-cost mass production. The first

microstructures molded in polymer materials were fabricated with

the well-known hot embossing process. The basic process steps are

depicted in Fig. 7.9. The microstructure is replicated by pressing a

master onto a substrate at temperatures above the substrate materi-

51

al's glass temperature. With the introduction of vacuum embossing

of plastics it became possible to imprint large areas uniformly since it

52

avoids an air cushion between stamp and sample. As the master

may be damaged by the embossing step, the so-called LIGA process

was adapted to fabricate a durable metal imprinting tool of the mas-

ter microstructure.

LIGA is the German acronym for the main steps of the process, i.e.,

lithography, electroforming, and plastic molding. 53–55 The single pro-

cess steps are shown in Fig. 7.10. To generate the metal tool by elec-

troforming the insulating master structure, a conducting starting

layer is deposited onto the master. This is usually done by evaporat-

ing a gold layer upon the master structure. By electroplating these

structures, the negative pattern of the resonator structure is formed as

a secondary metallic structure. Commonly used metals for plastic

Force

Heat

(a) (b) (c)

FIGURE 7.9 Processing steps for hot embossing.

(a) (b) (c)

FIGURE 7.10 Fabrication scheme of a Ni shim following the LIGA process.