Page 322 - Orlicky's Material Requirements Planning

P. 322

CHAPTER 17 Remanufacturing 301

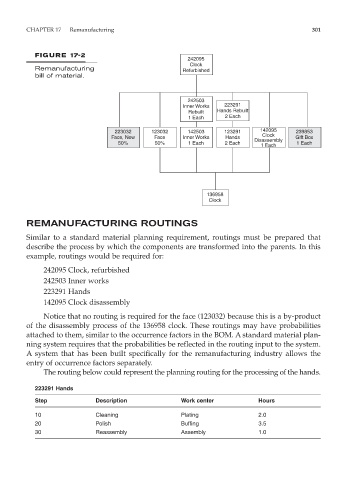

FIGURE 17-2

242095

Clock

Remanufacturing Refurbished

bill of material.

242503

Inner Works 223291

Rebuilt Hands Rebuilt

1 Each 2 Each

223032 123032 142503 123291 142095 239853

Clock

Face, New Face Inner Works Hands Disassembly Gift Box

50% 50% 1 Each 2 Each 1 Each

1 Each

136958

Clock

REMANUFACTURING ROUTINGS

Similar to a standard material planning requirement, routings must be prepared that

describe the process by which the components are transformed into the parents. In this

example, routings would be required for:

242095 Clock, refurbished

242503 Inner works

223291 Hands

142095 Clock disassembly

Notice that no routing is required for the face (123032) because this is a by-product

of the disassembly process of the 136958 clock. These routings may have probabilities

attached to them, similar to the occurrence factors in the BOM. A standard material plan-

ning system requires that the probabilities be reflected in the routing input to the system.

A system that has been built specifically for the remanufacturing industry allows the

entry of occurrence factors separately.

The routing below could represent the planning routing for the processing of the hands.

223291 Hands

Step Description Work center Hours

10 Cleaning Plating 2.0

20 Polish Buffing 3.5

30 Reassembly Assembly 1.0