Page 323 - Orlicky's Material Requirements Planning

P. 323

302 PART 3 Managing with the MRP System

Assuming that this routing is accurate, it still could be misleading. This routing

actually could be the planning for a product that really is requiring the following process:

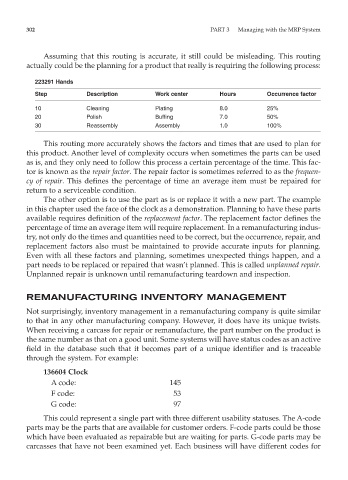

223291 Hands

Step Description Work center Hours Occurrence factor

10 Cleaning Plating 8.0 25%

20 Polish Buffing 7.0 50%

30 Reassembly Assembly 1.0 100%

This routing more accurately shows the factors and times that are used to plan for

this product. Another level of complexity occurs when sometimes the parts can be used

as is, and they only need to follow this process a certain percentage of the time. This fac-

tor is known as the repair factor. The repair factor is sometimes referred to as the frequen-

cy of repair. This defines the percentage of time an average item must be repaired for

return to a serviceable condition.

The other option is to use the part as is or replace it with a new part. The example

in this chapter used the face of the clock as a demonstration. Planning to have these parts

available requires definition of the replacement factor. The replacement factor defines the

percentage of time an average item will require replacement. In a remanufacturing indus-

try, not only do the times and quantities need to be correct, but the occurrence, repair, and

replacement factors also must be maintained to provide accurate inputs for planning.

Even with all these factors and planning, sometimes unexpected things happen, and a

part needs to be replaced or repaired that wasn’t planned. This is called unplanned repair.

Unplanned repair is unknown until remanufacturing teardown and inspection.

REMANUFACTURING INVENTORY MANAGEMENT

Not surprisingly, inventory management in a remanufacturing company is quite similar

to that in any other manufacturing company. However, it does have its unique twists.

When receiving a carcass for repair or remanufacture, the part number on the product is

the same number as that on a good unit. Some systems will have status codes as an active

field in the database such that it becomes part of a unique identifier and is traceable

through the system. For example:

136604 Clock

A code: 145

F code: 53

G code: 97

This could represent a single part with three different usability statuses. The A-code

parts may be the parts that are available for customer orders. F-code parts could be those

which have been evaluated as repairable but are waiting for parts. G-code parts may be

carcasses that have not been examined yet. Each business will have different codes for