Page 354 - Orlicky's Material Requirements Planning

P. 354

CHAPTER 20 Sales and Operations Planning 333

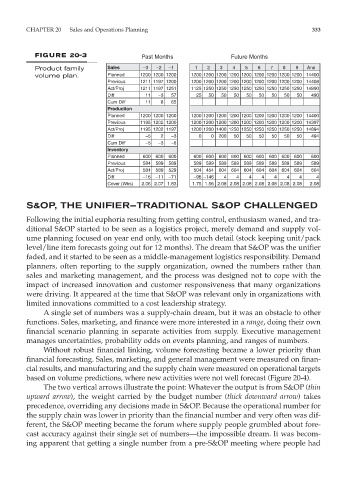

FIGURE 20-3 Past Months Future Months

Product family Sales –3 –2 –1 1 2 3 4 5 6 7 8 9 Ann

volume plan. Planned 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 14400

Previous 1211 1197 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 14408

Act/Proj 1211 1197 1251 1125 1250 1250 1250 1250 1250 1250 1250 1250 14890

Diff 11 –3 57 25 50 50 50 50 50 50 50 50 490

Cum Diff 11 8 65

Production

Planned 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 14400

Previous 1195 1202 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 14397

Act/Proj 1195 1202 1197 1200 1200 1400 1250 1250 1250 1250 1250 1250 14894

Diff –5 2 –3 0 0 200 50 50 50 50 50 50 494

Cum Diff –5 –3 –6

Inventory

Planned 600 600 600 600 600 600 600 600 600 600 600 600 600

Previous 584 589 589 589 589 589 589 589 589 589 589 589 589

Act/Proj 584 589 529 504 454 604 604 604 604 604 604 604 604

Diff –16 –11 –71 –96 –146 4 4 4 4 4 4 4 4

Cover (Wks) 2.06 2.07 1.83 1.75 1.56 2.08 2.08 2.08 2.08 2.08 2.08 2.08 2.08

S&OP, THE UNIFIER—TRADITIONAL S&OP CHALLENGED

Following the initial euphoria resulting from getting control, enthusiasm waned, and tra-

ditional S&OP started to be seen as a logistics project, merely demand and supply vol-

ume planning focused on year end only, with too much detail (stock keeping unit/pack

level/line item forecasts going out for 12 months). The dream that S&OP was the unifier

faded, and it started to be seen as a middle-management logistics responsibility. Demand

planners, often reporting to the supply organization, owned the numbers rather than

sales and marketing management, and the process was designed not to cope with the

impact of increased innovation and customer responsiveness that many organizations

were driving. It appeared at the time that S&OP was relevant only in organizations with

limited innovations committed to a cost leadership strategy.

A single set of numbers was a supply-chain dream, but it was an obstacle to other

functions. Sales, marketing, and finance were more interested in a range, doing their own

financial scenario planning in separate activities from supply. Executive management

manages uncertainties, probability odds on events planning, and ranges of numbers.

Without robust financial linking, volume forecasting became a lower priority than

financial forecasting. Sales, marketing, and general management were measured on finan-

cial results, and manufacturing and the supply chain were measured on operational targets

based on volume predictions, where new activities were not well forecast (Figure 20-4).

The two vertical arrows illustrate the point: Whatever the output is from S&OP (thin

upward arrow), the weight carried by the budget number (thick downward arrow) takes

precedence, overriding any decisions made in S&OP. Because the operational number for

the supply chain was lower in priority than the financial number and very often was dif-

ferent, the S&OP meeting became the forum where supply people grumbled about fore-

cast accuracy against their single set of numbers—the impossible dream. It was becom-

ing apparent that getting a single number from a pre-S&OP meeting where people had