Page 123 - PDA Robotics Using Your Personal Digital Assistant to Control Your Robot

P. 123

PDA 05 5/30/03 11:35 AM Page 99

Chapter 5 / The Electronics

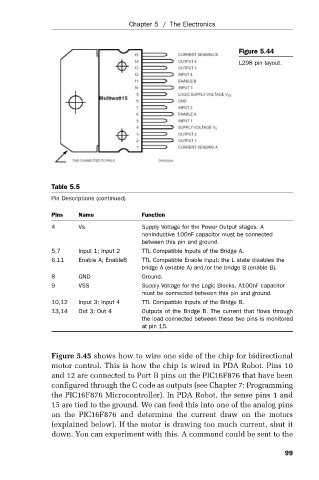

Figure 5.44

L298 pin layout.

Table 5.5

Pin Descriptions (continued)

Pins Name Function

4 Vs Supply Voltage for the Power Output stages. A

noninductive 100nF capacitor must be connected

between this pin and ground.

5,7 Input 1; Input 2 TTL Compatible Inputs of the Bridge A.

6,11 Enable A; EnableB TTL Compatible Enable Input: the L state disables the

bridge A (enable A) and/or the bridge B (enable B).

8 GND Ground.

9 VSS Supply Voltage for the Logic Blocks. A100nF capacitor

must be connected between this pin and ground.

10,12 Input 3; Input 4 TTL Compatible Inputs of the Bridge B.

13,14 Out 3; Out 4 Outputs of the Bridge B. The current that flows through

the load connected between these two pins is monitored

at pin 15.

Figure 5.45 shows how to wire one side of the chip for bidirectional

motor control. This is how the chip is wired in PDA Robot. Pins 10

and 12 are connected to Port B pins on the PIC16F876 that have been

configured through the C code as outputs (see Chapter 7: Programming

the PIC16F876 Microcontroller). In PDA Robot, the sense pins 1 and

15 are tied to the ground. We can feed this into one of the analog pins

on the PIC16F876 and determine the current draw on the motors

(explained below). If the motor is drawing too much current, shut it

down. You can experiment with this. A command could be sent to the

99