Page 107 - Packed bed columns for absorption, desorption, rectification and direct heat transfer

P. 107

102

concentrations of the gas and liquid phases. With increasing the height of the

packing, the end concentration of the gas phase decreases, and the accuracy of

its determination is reduced. On the other side, the reduction of the packing

height leads to increasing of the influence of the effects connected with initial

distribution of the phases and influence of the mass transfer on the drops and

jets between the liquid phase distributor and the packing, and after the packing

in the bottom of the column. That is why the experimental columns are to be

built in sections of different heights to provide the optimal height.

The more important parts of the column are the liquid phase distributor,

the supporting grid, the gas distributor, the separator of the liquid from the gas

phase entering the impulse pipes for measuring the pressure drop and the gas

phase concentrations, and the sampling device for the liquid phase under the

packing.

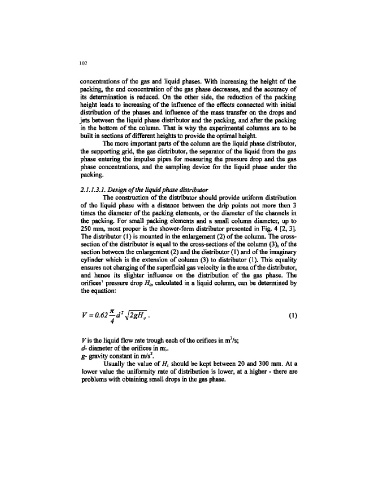

2,1.1.3.1. Design of the liquid phase distributor

The construction of the distributor should provide uniform distribution

of the liquid phase with a distance between the drip points not more then 3

times the diameter of the packing elements, or the diameter of the channels in

the packing. For small packing elements and a small column diameter, up to

250 mm, most proper is the shower-form distributor presented in Fig, 4 [2, 3],

The distributor (1) is mounted in the enlargement (2) of the column. The cross-

section of the distributor is equal to the cross-sections of the column (3), of the

section between the enlargement (2) and the distributor (1) and of the imaginary

cylinder which is the extension of column (3) to distributor (1). This equality

ensures not changing of the superficial gas velocity in the area of the distributor,

and hence its slighter influence on the distribution of the gas phase. The

5

orifices pressure drop H e, calculated in a liquid column, can be determined by

the equation:

(1)

3

Fis the liquid flow rate trough each of the orifices in m /s;

d- diameter of the orifices in m;.

2

g- gravity constant in m/s .

Usually the value of H c should be kept between 20 and 300 mm. At a

lower value the uniformity rate of distribution is lower, at a higher - there are

problems with obtaining small drops in the gas phase.