Page 108 - Packed bed columns for absorption, desorption, rectification and direct heat transfer

P. 108

103

Liquid

inlet

Gas

A outlet

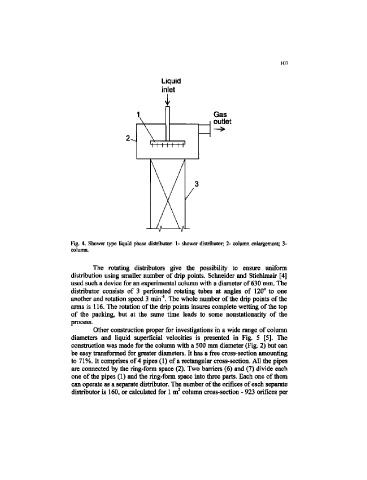

Fig. 4. Shower type liquid phase distributor: 1- shower distributor; 2- column enlargement; 3-

column.

The rotating distributors give the possibility to ensure uniform

distribution using smaller number of drip points. Schneider and Stichlmair [4]

used such a device for an experimental column with a diameter of 630 mm. The

distributor consists of 3 perforated rotating tubes at angles of 120° to one

1

another and rotation speed 3 min" . The whole number of the drip points of the

arms is 116. The rotation of the drip points insures complete wetting of the top

of the packing, but at the same time leads to some nonstationarity of the

process.

Other construction proper for investigations in a wide range of column

diameters and liquid superficial velocities is presented in Fig. 5 [5]. The

construction was made for the column with a 500 mm diameter (Fig. 2) but can

be easy transformed for greater diameters. It has a free cross-section amounting

to 71%. It comprises of 4 pipes (1) of a rectangular cross-section. All the pipes

are connected by the ring-form space (2). Two barriers (6) and (7) divide each

one of the pipes (1) and the ring-form space into three parts. Each one of them

can operate as a separate distributor. The number of the orifices of each separate

2

distributor is 160, or calculated for 1 m column cross-section - 923 orifices per