Page 112 - Petroleum and Gas Field Processing

P. 112

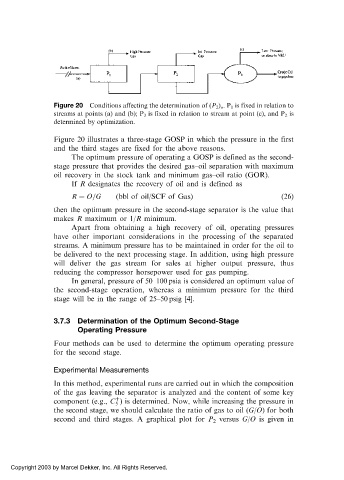

Figure 20 Conditions affecting the determination of (P 2 ) o .P 1 is fixed in relation to

streams at points (a) and (b); P 3 is fixed in relation to stream at point (c), and P 2 is

determined by optimization.

Figure 20 illustrates a three-stage GOSP in which the pressure in the first

and the third stages are fixed for the above reasons.

The optimum pressure of operating a GOSP is defined as the second-

stage pressure that provides the desired gas–oil separation with maximum

oil recovery in the stock tank and minimum gas–oil ratio (GOR).

If R designates the recovery of oil and is defined as

R ¼ O=G ðbbl of oil/SCF of Gas) ð26Þ

then the optimum pressure in the second-stage separator is the value that

makes R maximum or 1/R minimum.

Apart from obtaining a high recovery of oil, operating pressures

have other important considerations in the processing of the separated

streams. A minimum pressure has to be maintained in order for the oil to

be delivered to the next processing stage. In addition, using high pressure

will deliver the gas stream for sales at higher output pressure, thus

reducing the compressor horsepower used for gas pumping.

In general, pressure of 50–100 psia is considered an optimum value of

the second-stage operation, whereas a minimum pressure for the third

stage will be in the range of 25–50 psig [4].

3.7.3 Determination of the Optimum Second-Stage

Operating Pressure

Four methods can be used to determine the optimum operating pressure

for the second stage.

Experimental Measurements

In this method, experimental runs are carried out in which the composition

of the gas leaving the separator is analyzed and the content of some key

þ

component (e.g., C ) is determined. Now, while increasing the pressure in

5

the second stage, we should calculate the ratio of gas to oil (G/O) for both

second and third stages. A graphical plot for P 2 versus G/O is given in

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.