Page 275 - Petroleum and Gas Field Processing

P. 275

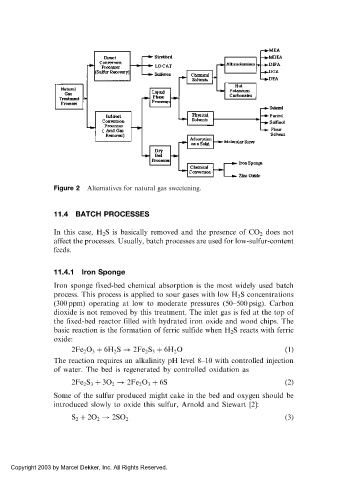

Figure 2 Alternatives for natural gas sweetening.

11.4 BATCH PROCESSES

In this case, H 2 S is basically removed and the presence of CO 2 does not

affect the processes. Usually, batch processes are used for low-sulfur-content

feeds.

11.4.1 Iron Sponge

Iron sponge fixed-bed chemical absorption is the most widely used batch

process. This process is applied to sour gases with low H 2 S concentrations

(300 ppm) operating at low to moderate pressures (50–500 psig). Carbon

dioxide is not removed by this treatment. The inlet gas is fed at the top of

the fixed-bed reactor filled with hydrated iron oxide and wood chips. The

basic reaction is the formation of ferric sulfide when H 2 S reacts with ferric

oxide:

2Fe 2 O 3 þ 6H 2 S ! 2Fe 2 S 3 þ 6H 2 O ð1Þ

The reaction requires an alkalinity pH level 8–10 with controlled injection

of water. The bed is regenerated by controlled oxidation as

2Fe 2 S 3 þ 3O 2 ! 2Fe 2 O 3 þ 6S ð2Þ

Some of the sulfur produced might cake in the bed and oxygen should be

introduced slowly to oxide this sulfur, Arnold and Stewart [2]:

S 2 þ 2O 2 ! 2SO 2 ð3Þ

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.