Page 276 - Petroleum and Gas Field Processing

P. 276

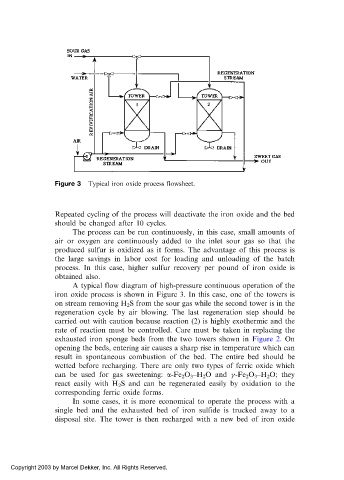

Figure 3 Typical iron oxide process flowsheet.

Repeated cycling of the process will deactivate the iron oxide and the bed

should be changed after 10 cycles.

The process can be run continuously, in this case, small amounts of

air or oxygen are continuously added to the inlet sour gas so that the

produced sulfur is oxidized as it forms. The advantage of this process is

the large savings in labor cost for loading and unloading of the batch

process. In this case, higher sulfur recovery per pound of iron oxide is

obtained also.

A typical flow diagram of high-pressure continuous operation of the

iron oxide process is shown in Figure 3. In this case, one of the towers is

on stream removing H 2 S from the sour gas while the second tower is in the

regeneration cycle by air blowing. The last regeneration step should be

carried out with caution because reaction (2) is highly exothermic and the

rate of reaction must be controlled. Care must be taken in replacing the

exhausted iron sponge beds from the two towers shown in Figure 2. On

opening the beds, entering air causes a sharp rise in temperature which can

result in spontaneous combustion of the bed. The entire bed should be

wetted before recharging. There are only two types of ferric oxide which

can be used for gas sweetening: a-Fe 2 O 3 –H 2 O and

-Fe 2 O 3 –H 2 O; they

react easily with H 2 S and can be regenerated easily by oxidation to the

corresponding ferric oxide forms.

In some cases, it is more economical to operate the process with a

single bed and the exhausted bed of iron sulfide is trucked away to a

disposal site. The tower is then recharged with a new bed of iron oxide

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.