Page 280 - Petroleum and Gas Field Processing

P. 280

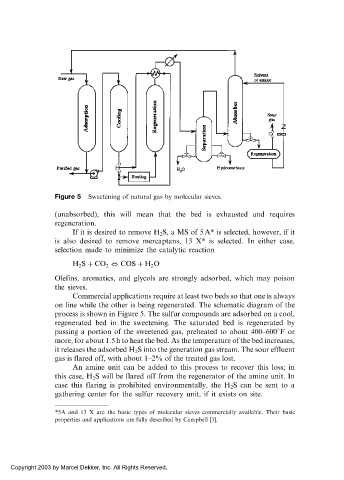

Figure 5 Sweetening of natural gas by molecular sieves.

(unabsorbed), this will mean that the bed is exhausted and requires

regeneration.

If it is desired to remove H 2 S, a MS of 5 A* is selected, however, if it

is also desired to remove mercaptans, 13 X* is selected. In either case,

selection made to minimize the catalytic reaction

H 2 S þ CO 2 , COS þ H 2 O

Olefins, aromatics, and glycols are strongly adsorbed, which may poison

the sieves.

Commercial applications require at least two beds so that one is always

on line while the other is being regenerated. The schematic diagram of the

process is shown in Figure 5. The sulfur compounds are adsorbed on a cool,

regenerated bed in the sweetening. The saturated bed is regenerated by

passing a portion of the sweetened gas, preheated to about 400–600 For

more, for about 1.5 h to heat the bed. As the temperature of the bed increases,

it releases the adsorbed H 2 S into the generation gas stream. The sour effluent

gas is flared off, with about 1–2% of the treated gas lost.

An amine unit can be added to this process to recover this loss; in

this case, H 2 S will be flared off from the regenerator of the amine unit. In

case this flaring is prohibited environmentally, the H 2 S can be sent to a

gathering center for the sulfur recovery unit, if it exists on site.

*5A and 13 X are the basic types of molecular sieves commercially available. Their basic

properties and applications are fully described by Campbell [3].

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.