Page 288 - Petroleum and Gas Field Processing

P. 288

when the CO 2 partial pressure is in the range 30–90 psi. The following

reactions occur in this case:

K 2 CO 3 þ CO 2 þ H 2 O , 2KHCO 3 ð12Þ

K 2 CO 3 þ H 2 S , KHS þ KHCO 3 ð13Þ

It can be seen from reaction (12) that a high partial pressure of CO 2 is

required to keep KHCO 3 in solution, and in Eq. (13), H 2 S will not react if

the CO 2 pressure is not high. For this reason, this process cannot achieve a

low concentration of acid gases in the exit stream and a polishing process

is needed (molecular sieve). An elevated temperature is also necessary to

ensure that potassium carbonate and reaction products (KHCO 3 and

KHS) remain in solution. Thus, this process cannot be used for gases

containing H 2 S only.

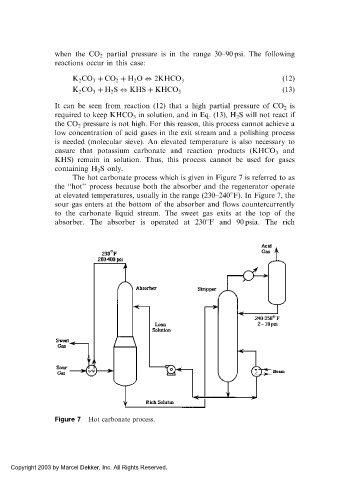

The hot carbonate process which is given in Figure 7 is referred to as

the ‘‘hot’’ process because both the absorber and the regenerator operate

at elevated temperatures, usually in the range (230–240 F). In Figure 7, the

sour gas enters at the bottom of the absorber and flows countercurrently

to the carbonate liquid stream. The sweet gas exits at the top of the

absorber. The absorber is operated at 230 F and 90 psia. The rich

Figure 7 Hot carbonate process.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.