Page 292 - Petroleum and Gas Field Processing

P. 292

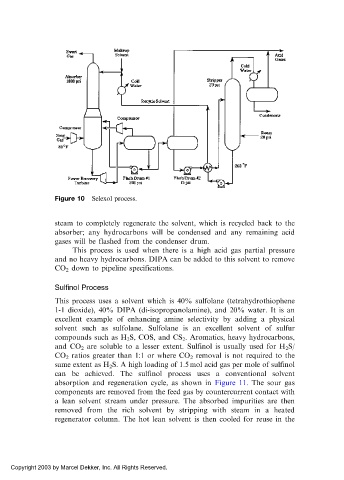

Figure 10 Selexol process.

steam to completely regenerate the solvent, which is recycled back to the

absorber; any hydrocarbons will be condensed and any remaining acid

gases will be flashed from the condenser drum.

This process is used when there is a high acid gas partial pressure

and no heavy hydrocarbons. DIPA can be added to this solvent to remove

CO 2 down to pipeline specifications.

Sulfinol Process

This process uses a solvent which is 40% sulfolane (tetrahydrothiophene

1-1 dioxide), 40% DIPA (di-isopropanolamine), and 20% water. It is an

excellent example of enhancing amine selectivity by adding a physical

solvent such as sulfolane. Sulfolane is an excellent solvent of sulfur

compounds such as H 2 S, COS, and CS 2 . Aromatics, heavy hydrocarbons,

and CO 2 are soluble to a lesser extent. Sulfinol is usually used for H 2 S/

CO 2 ratios greater than 1:1 or where CO 2 removal is not required to the

same extent as H 2 S. A high loading of 1.5 mol acid gas per mole of sulfinol

can be achieved. The sulfinol process uses a conventional solvent

absorption and regeneration cycle, as shown in Figure 11. The sour gas

components are removed from the feed gas by countercurrent contact with

a lean solvent stream under pressure. The absorbed impurities are then

removed from the rich solvent by stripping with steam in a heated

regenerator column. The hot lean solvent is then cooled for reuse in the

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.