Page 297 - Petroleum and Gas Field Processing

P. 297

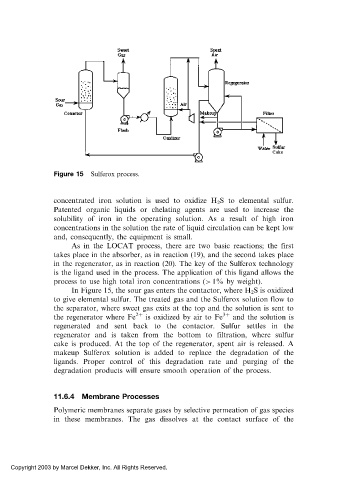

Figure 15 Sulferox process.

concentrated iron solution is used to oxidize H 2 S to elemental sulfur.

Patented organic liquids or chelating agents are used to increase the

solubility of iron in the operating solution. As a result of high iron

concentrations in the solution the rate of liquid circulation can be kept low

and, consequently, the equipment is small.

As in the LOCAT process, there are two basic reactions; the first

takes place in the absorber, as in reaction (19), and the second takes place

in the regenerator, as in reaction (20). The key of the Sulferox technology

is the ligand used in the process. The application of this ligand allows the

process to use high total iron concentrations (> 1% by weight).

In Figure 15, the sour gas enters the contactor, where H 2 S is oxidized

to give elemental sulfur. The treated gas and the Sulferox solution flow to

the separator, where sweet gas exits at the top and the solution is sent to

the regenerator where Fe 2þ is oxidized by air to Fe 3þ and the solution is

regenerated and sent back to the contactor. Sulfur settles in the

regenerator and is taken from the bottom to filtration, where sulfur

cake is produced. At the top of the regenerator, spent air is released. A

makeup Sulferox solution is added to replace the degradation of the

ligands. Proper control of this degradation rate and purging of the

degradation products will ensure smooth operation of the process.

11.6.4 Membrane Processes

Polymeric membranes separate gases by selective permeation of gas species

in these membranes. The gas dissolves at the contact surface of the

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.