Page 295 - Petroleum and Gas Field Processing

P. 295

4NaVO 3 þ 2NaHS þ H 2 O ¼ Na 2 V 4 O 9 þ 4NaOH þ 2S ð16Þ

Na 2 V 4 O 9 þ 2NaOH þ H 2 O þ 2ADAðquinoneÞ

¼ 4NaVO 3 þ 2ADAðhydroquinoneÞ ð17Þ

1

ADAðhydroquinoneÞþ O ¼ ADAðquinoneÞ ð18Þ

2

2

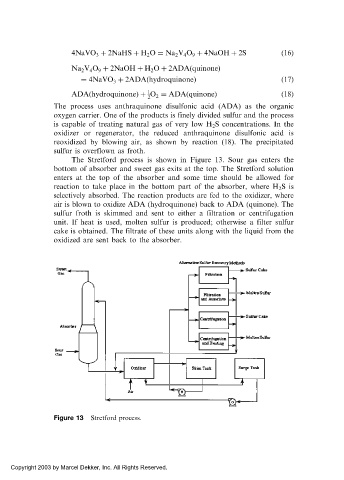

The process uses anthraquinone disulfonic acid (ADA) as the organic

oxygen carrier. One of the products is finely divided sulfur and the process

is capable of treating natural gas of very low H 2 S concentrations. In the

oxidizer or regenerator, the reduced anthraquinone disulfonic acid is

reoxidized by blowing air, as shown by reaction (18). The precipitated

sulfur is overflown as froth.

The Stretford process is shown in Figure 13. Sour gas enters the

bottom of absorber and sweet gas exits at the top. The Stretford solution

enters at the top of the absorber and some time should be allowed for

reaction to take place in the bottom part of the absorber, where H 2 Sis

selectively absorbed. The reaction products are fed to the oxidizer, where

air is blown to oxidize ADA (hydroquinone) back to ADA (quinone). The

sulfur froth is skimmed and sent to either a filtration or centrifugation

unit. If heat is used, molten sulfur is produced; otherwise a filter sulfur

cake is obtained. The filtrate of these units along with the liquid from the

oxidized are sent back to the absorber.

Figure 13 Stretford process.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.