Page 291 - Petroleum and Gas Field Processing

P. 291

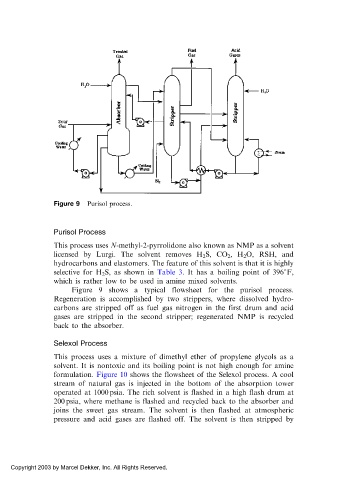

Figure 9 Purisol process.

Purisol Process

This process uses N-methyl-2-pyrrolidone also known as NMP as a solvent

licensed by Lurgi. The solvent removes H 2 S, CO 2 ,H 2 O, RSH, and

hydrocarbons and elastomers. The feature of this solvent is that it is highly

selective for H 2 S, as shown in Table 3. It has a boiling point of 396 F,

which is rather low to be used in amine mixed solvents.

Figure 9 shows a typical flowsheet for the purisol process.

Regeneration is accomplished by two strippers, where dissolved hydro-

carbons are stripped off as fuel gas nitrogen in the first drum and acid

gases are stripped in the second stripper; regenerated NMP is recycled

back to the absorber.

Selexol Process

This process uses a mixture of dimethyl ether of propylene glycols as a

solvent. It is nontoxic and its boiling point is not high enough for amine

formulation. Figure 10 shows the flowsheet of the Selexol process. A cool

stream of natural gas is injected in the bottom of the absorption tower

operated at 1000 psia. The rich solvent is flashed in a high flash drum at

200 psia, where methane is flashed and recycled back to the absorber and

joins the sweet gas stream. The solvent is then flashed at atmospheric

pressure and acid gases are flashed off. The solvent is then stripped by

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.