Page 293 - Petroleum and Gas Field Processing

P. 293

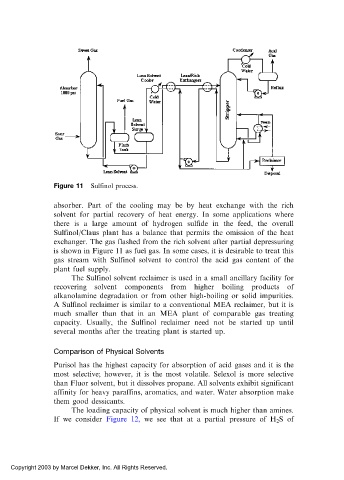

Figure 11 Sulfinol process.

absorber. Part of the cooling may be by heat exchange with the rich

solvent for partial recovery of heat energy. In some applications where

there is a large amount of hydrogen sulfide in the feed, the overall

Sulfinol/Claus plant has a balance that permits the omission of the heat

exchanger. The gas flashed from the rich solvent after partial depressuring

is shown in Figure 11 as fuel gas. In some cases, it is desirable to treat this

gas stream with Sulfinol solvent to control the acid gas content of the

plant fuel supply.

The Sulfinol solvent reclaimer is used in a small ancillary facility for

recovering solvent components from higher boiling products of

alkanolamine degradation or from other high-boiling or solid impurities.

A Sulfinol reclaimer is similar to a conventional MEA reclaimer, but it is

much smaller than that in an MEA plant of comparable gas treating

capacity. Usually, the Sulfinol reclaimer need not be started up until

several months after the treating plant is started up.

Comparison of Physical Solvents

Purisol has the highest capacity for absorption of acid gases and it is the

most selective; however, it is the most volatile. Selexol is more selective

than Fluor solvent, but it dissolves propane. All solvents exhibit significant

affinity for heavy paraffins, aromatics, and water. Water absorption make

them good dessicants.

The loading capacity of physical solvent is much higher than amines.

If we consider Figure 12, we see that at a partial pressure of H 2 Sof

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.