Page 114 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 114

5/91

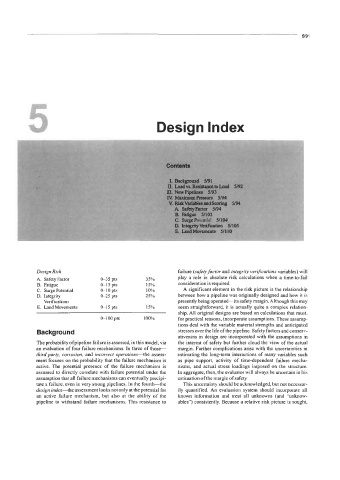

Design Index

5110

10

Design Risk failure (sufetyfuctor and integrity verifications variables) will

A. Safety Factor 0-35 pts 35% play a role in absolute risk calculations when a time-to-fail

B. Fatigue 0-15 pts 15% consideration is required.

C. Surge Potential 0-10 pts 10% A significant element in the risk picture is the relationship

D. Integrity 0-25 pts 25% between how a pipeline was originally designed and how it is

Verifications presently being operated-its safety margin. Although this may

E. Land Movements 0-15 pts 15% seem straightforward, it is actually quite a complex relation-

ship. All original designs are based on calculations that must,

0-100 pts 100% for practical reasons, incorporate assumptions. These assump-

tions deal with the variable material strengths and anticipated

Background stresses over the life of the pipeline. Safety factors and conserv-

ativeness in design are incorporated with the assumptions in

The probability of pipeline failure is assessed, in this model, via the interest of safety but further cloud the view of the actual

an evaluation of four failure mechanisms. In three of thos- margin. Further complications arise with the uncertainties in

third par& corrosion, and incorrect operations-the assess- estimating the long-term interactions of many variables such

ment focuses on the probability that the failure mechanism is as pipe support, activity of time-dependent failure mecha-

active. The potential presence of the failure mechanism is nisms, and actual stress loadings imposed on the structure.

assumed to directly correlate with failure potential under the In aggregate, then, the evaluator will always be uncertain in his

assumption that all failure mechanisms can eventually precipi- estimation ofthe margin of safety

tate a failure, even in very strong pipelines. In the fourth-the This uncertainty should be acknowledged, but not necessar-

design index-the assessment looks not only at the potential for ily quantified. An evaluation system should incorporate all

an active failure mechanism, but also at the ability of the known information and treat all unknowns (and “unknow-

pipeline to withstand failure mechanisms. This resistance to ables”) consistently. Because a relative risk picture is sought,