Page 111 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 111

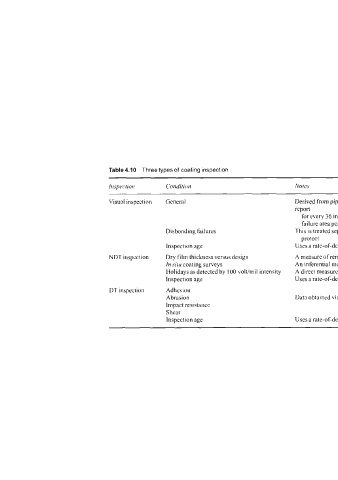

Table 4.10 Three types of coating inspection

~~~~

Inspec tion Condition Notes

~~ ~~ ~

Visual inspection General Derived from pipe inspection reports; inspection reports could be generated for each diameter length (36-111. pipe needs a

report

for every 36 in. of exposed pipe); inspector notes the beginning and end station of all anomalies; measures the percent

failure area per square foot of surface area.

Disbonding failures This is treated separately from other failure types since this failure mode is more problematic than othersdifficult to

protect.

Inspection age Uses a rate-of-decay of inspection results 4der inspections yield less useful risk information,

NDT inspection Dry film thickness versus design A measure of remaining coating.

In situ coating surveys An inferential measure of coating coverage and integrity.

Holidays as detected by IO0 volt/mil intensity A direct measure of coating integrity available during excavation and visual inspection.

Inspection age Uses a rate-of-decay of inspection results-dder inspections yield less useful risk information.

DT inspection Adhesion

Abrasion Data obtained via laboratory or on-site tests ofcoating samples obtained from field investigations

Impact resistance

Shear

Inspection age Uses a rate-of-decay of inspection results--older inspections yield less useful risk information.