Page 106 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 106

4/84 Corrosion Index

causing coating or metal

Magnetic or electric

I')r field sets up current

flow in pipeline

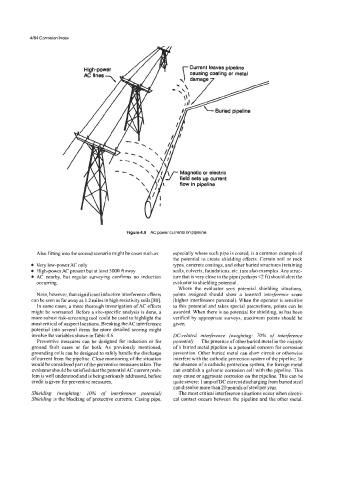

Figure 4.8 AC power currents on pipeline

Also fitting into the second scenario might be cases such as especially where such pipe is coated, is a common example of

the potential to create shielding effects. Certain soil or rock

Very low-power AC only types. concrete coatings, and other buried structures (retaining

High-power AC present but at least 3000 ft away walls, culverts, foundations, etc.) are also examples. Any struc-

AC nearby, but regular surveying confirms no induction ture that is very close to the pipe (perhaps <2 ft) should alert the

occurring. evaluator to shielding potential.

Where the evaluator sees potential shielding situations,

Note, however, that significant inductive interference effects points assigned should show a lowered interference score

can be seen as far away as 1.2 miles in high resistivity soils [SO]. (higher interference potential). When the operator is sensitive

In some cases, a more thorough investigation of AC effects to this potential and takes special precautions, points can be

might be warranted. Before a site-specific analysis is done, a awarded. When there is no potential for shielding, as has been

more robust risk-screening tool could be used to highlight the verified by appropriate surveys, maximum points should be

most critical of suspect locations. Breaking the AC interference given.

potential into several items for more detailed scoring might

involve the variables shown inTable 4.6. DC-related interference (weighting: 70% of interference

Preventive measures can be designed for induction or for potential) The presence of other buried metal in the vicinity

ground fault cases or for both. As previously mentioned, of a buried metal pipeline is a potential concern for corrosion

grounding cells can be designed to safely handle the discharge prevention. Other buried metal can short circuit or otherwise

of current from the pipeline. Close monitoring of the situation interfere with the cathodic protection system of the pipeline. In

would be considered part ofthe preventive measures taken. The the absence of a cathodic protection system, the foreign metal

evaluator should be satisfied that the potential AC current prob- can establish a galvanic corrosion cell with the pipeline. This

lem is well understood and is being seriously addressed, before may cause or aggravate corrosion on the pipeline. This can be

credit is given for preventive measures. quite severe: 1 amp ofDC current discharging from buried steel

can dissolve more than 20 pounds of steel per year.

Shielding (weighting: 10% of interference potential) The most critical interference situations occur when electri-

Shielding is the blocking of protective currents. Casing pipe, cal contact occurs between the pipeline and the other metal.