Page 140 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 140

611 17

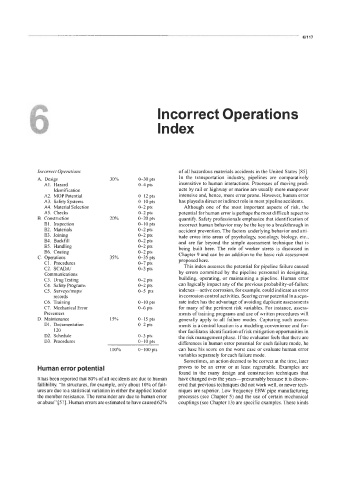

I n cor rect Ope rat ions

Index

Incorrect Operations of all hazardous materials accidents in the United States [85].

A. Design 30% 0-30 pts In the transportation industry, pipelines are comparatively

AI. Hazard &4 pts insensitive to human interactions. Processes of moving prod-

Identification ucts by rail or highway or marine are usually more manpower

A2. MOP Potential 0-12 pts intensive and, hence, more error prone. However, human error

A3. Safety Systems 0-10 pts has played a direct or indirect role in most pipeline accidents.

A4. Material Selection 0-2 pts Although one of the most important aspects of risk, the

A5. Checks 0-2 pts potential for human error is perhaps the most difficult aspect to

B. Construction 20% 0-20 pts quantify. Safety professionals emphasize that identification of

B 1. Inspection 0-10 pts incorrect human behavior may be the key to a breakthrough in

B2. Materials 0-2 pts accident prevention. The factors underlying behavior and atti-

B3. Joining 0-2 pts tude cross into areas of psychology, sociology, biology, etc.,

B4. Backfill 0-2 pts and are far beyond the simple assessment technique that is

B5. Handling 0-2 pts being built here. The role of worker stress is discussed in

B6. Coating 0-2 pts

C. Operations 35% 0-35 pts Chapter 9 and can be an addition to the basic risk assessment

C 1. Procedures 0-1 pts proposed here.

C2. SCADN 0-3 pts This index assesses the potential for pipeline failure caused

Communications by errors committed by the pipeline personnel in designing,

C3. DrugTesting 0-2 pts building, operating, or maintaining a pipeline. Human error

C4. Safety Programs 0-2 pts can logically impact any of the previous probability-of-failure

C5. Surveysimapsl 0-5 pts indexes-active corrosion, for example, could indicate an error

records in corrosion control activities. Scoring error potential in a sepa-

C6. Training 0-10 pts rate index has the advantage of avoiding duplicate assessments

C7. Mechanical Error 06 pts for many of the pertinent risk variables. For instance, assess-

Preventers ments of training programs and use of written procedures will

D. Maintenance 15% 0-15 pts generally apply to all failure modes. Capturing such assess-

D1. Documentation &2 pts ments in a central location is a modeling convenience and fur-

120 ther facilitates identification of risk mitigation opportunities in

D2. Schedule 0-3 pts the risk management phase. If the evaluator feels that there are

D3. Procedures 0-10 pts differences in human error potential for each failure mode, he

100% 0-100 pts can base his score on the worst case or evaluate human error

variables separately for each failure mode.

Sometimes, an action deemed to be correct at the time, later

Human error potential proves to be an error or at least regrettable. Examples are

found in the many design and construction techniques that

It has been reported that 80% of all accidents are due to human have changed over the years-presumably because it is discov-

fallibility. “In structures, for example, only about 10% of fail- ered that previous techniques did not work well, or newer tech-

ures are due to a statistical variation in either the applied load or niques are superior. Low frequency ERW pipe manufacturing

the member resistance. The remainder are due to human error processes (see Chapter 5) and the use of certain mechanical

or abuse” [57]. Human errors are estimated to have caused 62% couplings (see Chapter 13) are specific examples. These kinds