Page 312 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 312

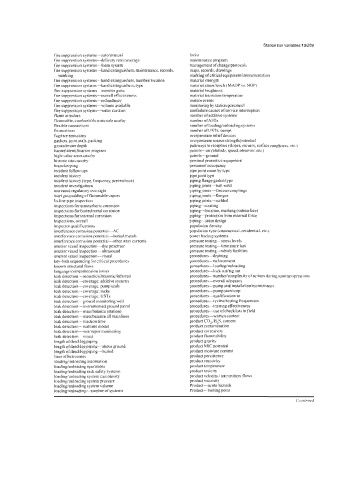

Station risk variables 131289

fire suppression systems-autoimanuai locks

fire suppression systems-delivery ratelcoverage maintenance program

fire suppression systems-foam system management of change protocols

fire suppression systems--hand extinguishers, maintenance, records, maps, records. drawings

marking marking of critical equipment/instrumentation

fire suppression systems- -hand extinguishers, numberilocation material strength

fire suppression systems-hand extinguishers, type material stress levels (MAOP vs. NOP)

fire suppression systems-monitor guns material toughness

fire suppression systems-overall effectiveness material transition temperature

fire suppression systems-redundancy meteor events

fire suppression systems-volume available monitoring by station personnel

fire suppression systems-water curtains nonfadure causes of service interruption

flame arrestors number of additive systems

flammable, combustible materials nearby number ofASTs

flexible connections number of loadmgiunloadiny systems

foundations number of USTs, sumps

fugitive emissions overpressure relief devices

gaskets. joint seals, packing overpressure source strengthlpotential

groundwater depth pathways to receptors (slopes, ravines, surface roughness. etc.)

hazard identification program patrols-air (altitude, speed observer. etc.)

high-value areas nearby patrols-ground

historic sites nearby personal protective equipment

housekeeping personnel occupancy

incident follow-ups pipe joint count by type

incident history pipe joint type

incident history (type. frequency, preventions) piping flange gasket type

incident investigations piping joints-butt weld

increased regulatory oversight piping joints-Dresser couplings

inert gas padding of flammable vapors piping joints-flanges

In-line pipe inspection piping joints-welded

inspections for atmospheric corrosion piping-coating

inspections for buried metal corrosion piping-location, marking (subsurface)

inspections for internal corrosion piping-protection from external force

Inspections, overall piping-semi design

inspector qualificationa population density

interference corrosion potential-AC population type (commercial. residential, etc.)

interference corrosion potential-buried metals power backup systems

interference corrosion potential--other stray currents pressure testing-stress levels

interior vessel inspectiondye penetrant pressure testing-time since last

interior vessel inspection-ultrasound pressure testing--which facilities

intenor vessel inspection-visual proceduresdraining

key-lock sequencing for critical procedures procedures-enforcement

known structural flaws procedures-loading/unloading

languageicomprehension issues procedures-lock oudtag out

leak detection-acousticlultrasoniciinfrared procedures-nurnber/complexity of actions during routine operations

leak detection-coverage: additive systems procedures-verall adequacy

leak detection--coverage: pump seals procedures-pump seal installationlmaintenance

leak detection--coverage: racks procedures-pump stadstop

leak detection--coverage: USTs procedures-qualification to

leak detection-ground monitoring well procedures-reviewltesting frequencies

leak detection-instrumented ground patrol procedures-training effectiveness

leak detection--mass balance (station) procedures-use of checklists in field

leak detection-mass balance all mainlines procedures-written content

leak detection-reaction time product CO,, H,S. content

leak detection-realtime model product contamination

leak detection-soilivapor monitoring product corrosivity

leak detection -visual product flammability

length of dead-leg piping product gravity

length of dead-leg piping-above ground product MIC potcntial

length of dead-leg piping-buried product moisture content

liner effectiveness product persistence

loadingiunloading automation product reactivity

loading/unloading operations product temperature

loading/unloading rack safety systems product toxicity

loading/unloadmg system complexity product velocity / intermitlent flows

loading/unloading system pressure product viscosity

loadinghloading system volume Product-acute hazards

loadingiunloading-number of systems Product-boiling point