Page 100 - Pipeline Rules of Thumb Handbook

P. 100

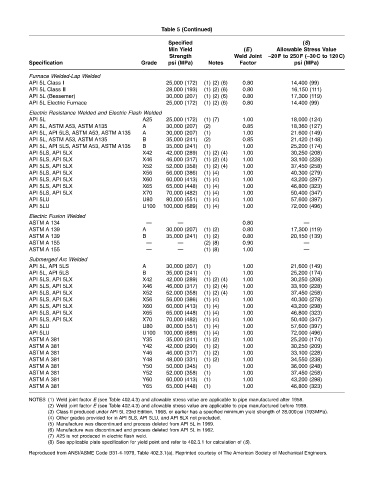

Table 5 (Continued)

Specified (S)

Min Yield (E ) Allowable Stress Value

Strength Weld Joint -20F to 250F (-30C to 120C)

Specification Grade psi (MPa) Notes Factor psi (MPa)

Furnace Welded-Lap Welded

API 5L Class I 25,000 (172) (1) (2) (6) 0.80 14,400 (99)

API 5L Class II 28,000 (193) (1) (2) (6) 0.80 16,150 (111)

API 5L (Bessemer) 30,000 (207) (1) (2) (6) 0.80 17,300 (119)

API 5L Electric Furnace 25,000 (172) (1) (2) (6) 0.80 14,400 (99)

Electric Resistance Welded and Electric Flash Welded

API 5L A25 25,000 (172) (1) (7) 1.00 18,000 (124)

API 5L, ASTM A53, ASTM A135 A 30,000 (207) (2) 0.85 18,360 (127)

API 5L, API 5LS, ASTM A53, ASTM A135 A 30,000 (207) (1) 1.00 21.600 (149)

API 5L, ASTM A53, ASTM A135 B 35,000 (241) (2) 0.85 21,420 (148)

API 5L, API 5LS, ASTM A53, ASTM A135 B 35,000 (241) (1) 1.00 25,200 (174)

API 5LS, API 5LX X42 42,000 (289) (1) (2) (4) 1.00 30,250 (208)

API 5LS, API 5LX X46 46,000 (317) (1) (2) (4) 1.00 33,100 (228)

API 5LS, API 5LX X52 52,000 (358) (1) (2) (4) 1.00 37,450 (258)

API 5LS, API 5LX X56 56,000 (386) (1) (4) 1.00 40,300 (279)

API 5LS, API 5LX X60 60,000 (413) (1) (4) 1.00 43,200 (297)

API 5LS, API 5LX X65 65,000 (448) (1) (4) 1.00 46,800 (323)

API 5LS, API 5LX X70 70,000 (482) (1) (4) 1.00 50,400 (347)

API 5LU U80 80,000 (551) (1) (4) 1.00 57,600 (397)

API 5LU U100 100,000 (689) (1) (4) 1.00 72,000 (496)

Electric Fusion Welded

ASTM A 134 — — 0.80 —

ASTM A 139 A 30,000 (207) (1) (2) 0.80 17,300 (119)

ASTM A 139 B 35,000 (241) (1) (2) 0.80 20,150 (139)

ASTM A 155 — — (2) (8) 0.90 —

ASTM A 155 — — (1) (8) 1.00 —

Submerged Arc Welded

API 5L, API 5LS A 30,000 (207) (1) 1.00 21,600 (149)

API 5L, API 5LS B 35,000 (241) (1) 1.00 25,200 (174)

API 5LS, API 5LX X42 42,000 (289) (1) (2) (4) 1.00 30,250 (208)

API 5LS, API 5LX X46 46,000 (317) (1) (2) (4) 1.00 33,100 (228)

API 5LS, API 5LX X52 52,000 (358) (1) (2) (4) 1.00 37,450 (258)

API 5LS, API 5LX X56 56,000 (386) (1) (4) 1.00 40,300 (278)

API 5LS, API 5LX X60 60,000 (413) (1) (4) 1.00 43,200 (298)

API 5LS, API 5LX X65 65,000 (448) (1) (4) 1.00 46,800 (323)

API 5LS, API 5LX X70 70,000 (482) (1) (4) 1.00 50,400 (347)

API 5LU U80 80,000 (551) (1) (4) 1.00 57,600 (397)

API 5LU U100 100,000 (689) (1) (4) 1.00 72,000 (496)

ASTM A 381 Y35 35,000 (241) (1) (2) 1.00 25,200 (174)

ASTM A 381 Y42 42,000 (290) (1) (2) 1.00 30,250 (209)

ASTM A 381 Y46 46,000 (317) (1) (2) 1.00 33,100 (228)

ASTM A 381 Y48 48,000 (331) (1) (2) 1.00 34,550 (238)

ASTM A 381 Y50 50,000 (345) (1) 1.00 36,000 (248)

ASTM A 381 Y52 52,000 (358) (1) 1.00 37,450 (258)

ASTM A 381 Y60 60,000 (413) (1) 1.00 43,200 (298)

ASTM A 381 Y65 65,000 (448) (1) 1.00 46,800 (323)

NOTES (1) Weld joint factor E (see Table 402.4.3) and allowable stress value are applicable to pipe manufactured after 1958.

(2) Weld joint factor E (see Table 402.4.3) and allowable stress value are applicable to pipe manufactured before 1959.

(3) Class II produced under API 5L 23rd Edition, 1968, or earlier has a specified minimum yield strength of 28,000psi (193MPa).

(4) Other grades provided for in API 5LS, API 5LU, and API 5LX not precluded.

(5) Manufacture was discontinued and process deleted from API 5L in 1969.

(6) Manufacture was discontinued and process deleted from API 5L in 1962.

(7) A25 is not produced in electric flash weld.

(8) See applicable plate specification for yield point and refer to 402.3.1 for calculation of (S).

Reproduced from ANSI/ASME Code B31-4-1979, Table 402.3.1(a). Reprinted courtesy of The American Society of Mechanical Engineers.