Page 168 - Pipeline Rules of Thumb Handbook

P. 168

Pipeline Drying 155

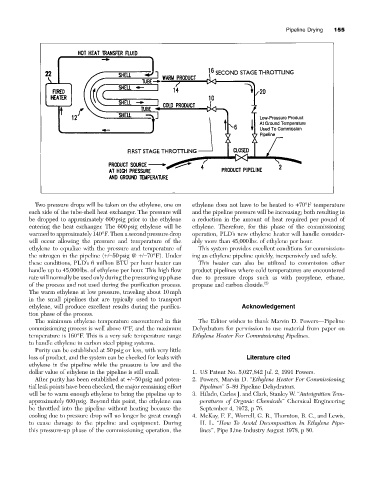

Two pressure drops will be taken on the ethylene, one on ethylene does not have to be heated to +70°F temperature

each side of the tube-shell heat exchanger. The pressure will and the pipeline pressure will be increasing; both resulting in

be dropped to approximately 600psig prior to the ethylene a reduction in the amount of heat required per pound of

entering the heat exchanger. The 600psig ethylene will be ethylene. Therefore, for this phase of the commissioning

warmed to approximately 140°F. Then a second pressure drop operation, PLD’s new ethylene heater will handle consider-

will occur allowing the pressure and temperature of the ably more than 45,000lbs. of ethylene per hour.

ethylene to equalize with the pressure and temperature of This system provides excellent conditions for commission-

the nitrogen in the pipeline (+/-50psig @ +/-70°F). Under ing an ethylene pipeline quickly, inexpensively and safely.

these conditions, PLD’s 6 million BTU per hour heater can This heater can also be utilized to commission other

handle up to 45,000lbs. of ethylene per hour. This high flow product pipelines where cold temperatures are encountered

rate will normally be used only during the pressuring up phase due to pressure drops such as with propylene, ethane,

of the process and not used during the purification process. propane and carbon dioxide. (2)

The warm ethylene at low pressure, traveling about 10mph

in the small pipelines that are typically used to transport

ethylene, will produce excellent results during the purifica- Acknowledgement

tion phase of the process.

The minimum ethylene temperature encountered in this The Editor wishes to thank Marvin D. Powers—Pipeline

commissioning process is well above 0°F, and the maximum Dehydrators for permission to use material from paper on

temperature is 160°F. This is a very safe temperature range Ethylene Heater For Commissioning Pipelines.

to handle ethylene in carbon steel piping systems.

Purity can be established at 50psig or less, with very little

loss of product, and the system can be checked for leaks with Literature cited

ethylene in the pipeline while the pressure is low and the

dollar value of ethylene in the pipeline is still small. 1. US Patent No. 5,027,842 Jul. 2, 1991 Powers.

After purity has been established at +/-50psig and poten- 2. Powers, Marvin D. “Ethylene Heater For Commissioning

tial leak points have been checked, the major remaining effort Pipelines” 5–89 Pipeline Dehydrators.

will be to warm enough ethylene to bring the pipeline up to 3. Hilado, Carlos J. and Clark, Stanley W. “Autoignition Tem-

approximately 600psig. Beyond this point, the ethylene can peratures of Organic Chemicals” Chemical Engineering

be throttled into the pipeline without heating because the September 4, 1972, p 76.

cooling due to pressure drop will no longer be great enough 4. McKay, F. F., Worrell, G. R., Thornton, B. C., and Lewis,

to cause damage to the pipeline and equipment. During H. L. “How To Avoid Decomposition In Ethylene Pipe-

this pressure-up phase of the commissioning operation, the lines”, Pipe Line Industry August 1978, p 80.