Page 169 - Pipeline Rules of Thumb Handbook

P. 169

156 Pipeline Rules of Thumb Handbook

Vacuum drying

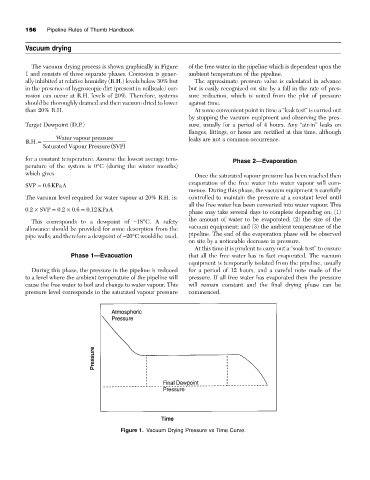

The vacuum drying process is shown graphically in Figure of the free water in the pipeline which is dependent upon the

1 and consists of three separate phases. Corrosion is gener- ambient temperature of the pipeline.

ally inhibited at relative humidity (R.H.) levels below 30% but The approximate pressure value is calculated in advance

in the presence of hygroscopic dirt (present in millscale) cor- but is easily recognized on site by a fall in the rate of pres-

rosion can occur at R.H. levels of 20%. Therefore, systems sure reduction, which is noted from the plot of pressure

should be thoroughly drained and then vacuum dried to lower against time.

than 20% R.H. At some convenient point in time a “leak test” is carried out

by stopping the vacuum equipment and observing the pres-

Target Dewpoint (D.P.) sure, usually for a period of 4 hours. Any “air-in” leaks on

flanges, fittings, or hoses are rectified at this time, although

Water vapour pressure leaks are not a common occurrence.

RH.. =

(

Saturated Vapour Pr essure SVP)

for a constant temperature. Assume the lowest average tem-

Phase 2—Evaporation

perature of the system is 0°C (during the winter months)

which gives Once the saturated vapour pressure has been reached then

evaporation of the free water into water vapour will com-

SVP = 0.6KPaA

mence. During this phase, the vacuum equipment is carefully

The vacuum level required for water vapour at 20% R.H. is: controlled to maintain the pressure at a constant level until

all the free water has been converted into water vapour. This

0.2 ¥ SVP = 0.2 ¥ 0.6 = 0.12KPaA phase may take several days to complete depending on: (1)

This corresponds to a dewpoint of -18°C. A safety the amount of water to be evaporated; (2) the size of the

allowance should be provided for some desorption from the vacuum equipment; and (3) the ambient temperature of the

pipe walls; and therefore a dewpoint of -20°C would be used. pipeline. The end of the evaporation phase will be observed

on site by a noticeable decrease in pressure.

At this time it is prudent to carry out a “soak test” to ensure

Phase 1—Evacuation that all the free water has in fact evaporated. The vacuum

equipment is temporarily isolated from the pipeline, usually

During this phase, the pressure in the pipeline is reduced for a period of 12 hours, and a careful note made of the

to a level where the ambient temperature of the pipeline will pressure. If all free water has evaporated then the pressure

cause the free water to boil and change to water vapour. This will remain constant and the final drying phase can be

pressure level corresponds to the saturated vapour pressure commenced.

Figure 1. Vacuum Drying Pressure vs Time Curve.