Page 268 - Pipeline Rules of Thumb Handbook

P. 268

Gas—General 255

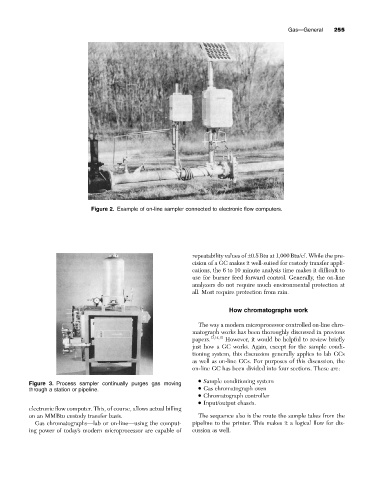

Figure 2. Example of on-line sampler connected to electronic flow computers.

repeatability values of ±0.5Btu at 1,000Btu/cf. While the pre-

cision of a GC makes it well-suited for custody transfer appli-

cations, the 6 to 10 minute analysis time makes it difficult to

use for burner feed forward control. Generally, the on-line

analyzers do not require much environmental protection at

all. Most require protection from rain.

How chromatographs work

The way a modern microprocessor controlled on-line chro-

matograph works has been thoroughly discussed in previous

papers. 13,14,15 However, it would be helpful to review briefly

just how a GC works. Again, except for the sample condi-

tioning system, this discussion generally applies to lab GCs

as well as on-line GCs. For purposes of this discussion, the

on-line GC has been divided into four sections. These are:

Figure 3. Process sampler continually purges gas moving • Sample conditioning system

through a station or pipeline. • Gas chromatograph oven

• Chromatograph controller

• Input/output chassis.

electronic flow computer. This, of course, allows actual billing

on an MMBtu custody transfer basis. The sequence also is the route the sample takes from the

Gas chromatographs—lab or on-line—using the comput- pipeline to the printer. This makes it a logical flow for dis-

ing power of today’s modern microprocessor are capable of cussion as well.