Page 77 - Pipeline Rules of Thumb Handbook

P. 77

64 Pipeline Rules of Thumb Handbook

It is the responsibility of the stringer bead crew to mini-

mize wagon tracks and the responsibility of the hot pass crew

5

to burn them out. This is normally done with / 32 ≤ (4.0mm)

electrode at about 175–180amps. The secret in melting out

wagon tracks lies primarily in the skill of the hot pass crew

and the penetration factor of the electrode. The majority of

the hot pass men use a rapid stitching technique which

Figure 10. Any deep surface ripples located directly above a exposes the wagon track momentarily and permits them to

point adjacent to the inside bead will contribute to a dark direct the arc into the undercut area and melt them out.

shading of the film at this area. This has been misinterpreted by The depth of the wagon tracks may be affected by the

some as internal undercut.

following:

Condition Results

Bevel too small (Figure 12). Increases depth of W.T.

Root Spacing (Gap) too small. Increases depth of W.T.

Figure 11. “Wagon tracks” are located on either side of the Current and/or speed too high. Increases depth of W.T.

stringer bead.

In extremes, it may be necessary to use a grinder to open up

Although this darker area is considerably wider than any the sidewalls to minimize deep “wagon tracks” or, if they do

undercut, it has been mistaken for undercut and resulted in occur, to grind the stringer to eliminate the high peaked

cutting out good welds. Normally, a “stout” inside bead is con- center (Figure 13). In all cases a / 32 ≤ (4.0mm) thickness disc

5

sidered good, but in this instance, the stouter the bead, the grinder should be used to grind root beads on all pipe from

1

darker the adjacent area would appear (Figure 10). 12≤ (304.8mm) up irrespective of wall thickness [a / 8 ≤

(3.2mm) disc grinder will grind the center and roll the sides

over on the wagon track unless side pressure is applied]. This

Wagon tracks will make it easier to melt them out.

If the stringer bead tends to wander to one side or the

It is not possible to completely eliminate the sidewall other, it will leave a deep undercut on the shallow side. This

undercut produced by the stringer bead. This condition is condition should be corrected immediately by changing the

generally referred to as “wagon tracks” (Figures 4 and 11). electrode angle (Figure 14).

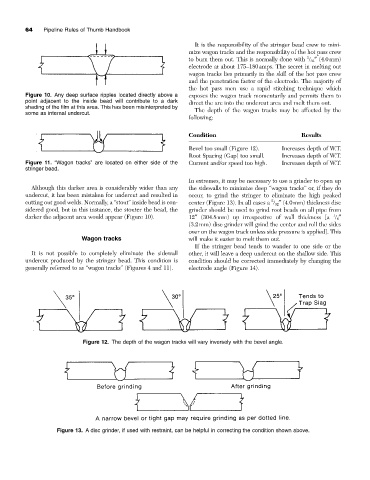

Figure 12. The depth of the wagon tracks will vary inversely with the bevel angle.

Figure 13. A disc grinder, if used with restraint, can be helpful in correcting the condition shown above.