Page 78 - Pipeline Rules of Thumb Handbook

P. 78

Construction 65

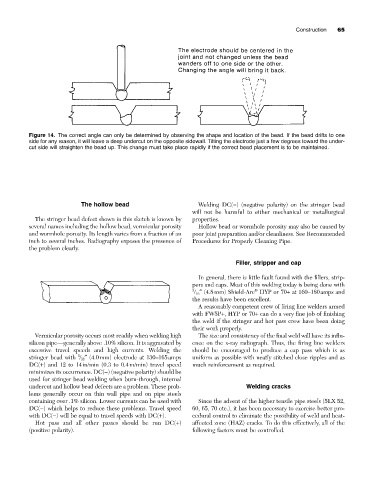

Figure 14. The correct angle can only be determined by observing the shape and location of the bead. If the bead drifts to one

side for any reason, it will leave a deep undercut on the opposite sidewall. Tilting the electrode just a few degrees toward the under-

cut side will straighten the bead up. This change must take place rapidly if the correct bead placement is to be maintained.

The hollow bead Welding DC(-) (negative polarity) on the stringer bead

will not be harmful to either mechanical or metallurgical

The stringer bead defect shown in this sketch is known by properties.

several names including the hollow bead, vermicular porosity Hollow bead or wormhole porosity may also be caused by

and wormhole porosity. Its length varies from a fraction of an poor joint preparation and/or cleanliness. See Recommended

inch to several inches. Radiography exposes the presence of Procedures for Properly Cleaning Pipe.

the problem clearly.

Filler, stripper and cap

In general, there is little fault found with the fillers, strip-

pers and caps. Most of this welding today is being done with

®

3 / 16 ≤ (4.8mm) Shield-Arc HYP or 70+ at 160–180amps and

the results have been excellent.

A reasonably competent crew of firing line welders armed

with FW5P+, HYP or 70+ can do a very fine job of finishing

the weld if the stringer and hot pass crew have been doing

their work properly.

Vermicular porosity occurs most readily when welding high The size and consistency of the final weld will have its influ-

silicon pipe—generally above .10% silicon. It is aggravated by ence on the x-ray radiograph. Thus, the firing line welders

excessive travel speeds and high currents. Welding the should be encouraged to produce a cap pass which is as

5

stringer bead with / 32 ≤ (4.0mm) electrode at 130–165amps uniform as possible with neatly stitched close ripples and as

DC(+) and 12 to 14in/min (0.3 to 0.4m/min) travel speed much reinforcement as required.

minimizes its occurrence. DC(-) (negative polarity) should be

used for stringer bead welding when burn-through, internal

undercut and hollow bead defects are a problem. These prob- Welding cracks

lems generally occur on thin wall pipe and on pipe steels

containing over .1% silicon. Lower currents can be used with Since the advent of the higher tensile pipe steels (5LX 52,

DC(-) which helps to reduce these problems. Travel speed 60, 65, 70 etc.), it has been necessary to exercise better pro-

with DC(-) will be equal to travel speeds with DC(+). cedural control to eliminate the possibility of weld and heat-

Hot pass and all other passes should be run DC(+) affected zone (HAZ) cracks. To do this effectively, all of the

(positive polarity). following factors must be controlled.