Page 75 - Pipeline Rules of Thumb Handbook

P. 75

62 Pipeline Rules of Thumb Handbook

(or ground). However, this clean-up operation should never

produce an internal chamfer. A condition such as this is

almost certain to result in “internal undercut” (Figure 7). See

Recommended Procedures for Cleaning Pipe on the previous

page.

Undercut vs. welding current

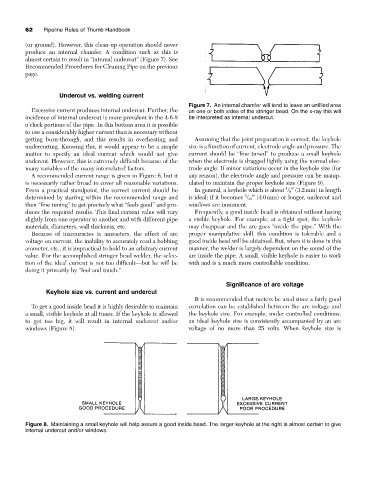

Figure 7. An internal chamfer will tend to leave an unfilled area

Excessive current produces internal undercut. Further, the on one or both sides of the stringer bead. On the x-ray this will

incidence of internal undercut is more prevalent in the 4-6-8 be interpreted as internal undercut.

o’clock portions of the pipe. In this bottom area it is possible

to use a considerably higher current than is necessary without

getting burn-through, and this results in overheating and Assuming that the joint preparation is correct, the keyhole

undercutting. Knowing this, it would appear to be a simple size is a function of current, electrode angle and pressure. The

matter to specify an ideal current which would not give current should be “fine tuned” to produce a small keyhole

undercut. However, this is extremely difficult because of the when the electrode is dragged lightly using the normal elec-

many variables of the many interrelated factors. trode angle. If minor variations occur in the keyhole size (for

A recommended current range is given in Figure 6, but it any reason), the electrode angle and pressure can be manip-

is necessarily rather broad to cover all reasonable variations. ulated to maintain the proper keyhole size (Figure 9).

1

From a practical standpoint, the correct current should be In general, a keyhole which is about / 8 ≤ (3.2mm) in length

5

determined by starting within the recommended range and is ideal; if it becomes / 32 ≤ (4.0mm) or longer, undercut and

then “fine tuning” to get precisely what “feels good” and pro- windows are imminent.

duces the required results. This final current value will vary Frequently, a good inside bead is obtained without having

slightly from one operator to another and with different pipe a visible keyhole. For example, at a tight spot, the keyhole

materials, diameters, wall thickness, etc. may disappear and the arc goes “inside the pipe.” With the

Because of inaccuracies in ammeters, the effect of arc proper manipulative skill, this condition is tolerable and a

voltage on current, the inability to accurately read a bobbing good inside bead will be obtained. But, when it is done in this

ammeter, etc., it is impractical to hold to an arbitrary current manner, the welder is largely dependent on the sound of the

value. For the accomplished stringer bead welder, the selec- arc inside the pipe. A small, visible keyhole is easier to work

tion of the ideal current is not too difficult—but he will be with and is a much more controllable condition.

doing it primarily by “feel and touch.”

Significance of arc voltage

Keyhole size vs. current and undercut

It is recommended that meters be used since a fairly good

To get a good inside bead it is highly desirable to maintain correlation can be established between the arc voltage and

a small, visible keyhole at all times. If the keyhole is allowed the keyhole size. For example, under controlled conditions,

to get too big, it will result in internal undercut and/or an ideal keyhole size is consistently accompanied by an arc

windows (Figure 8). voltage of no more than 25 volts. When keyhole size is

Figure 8. Maintaining a small keyhole will help assure a good inside bead. The larger keyhole at the right is almost certain to give

internal undercut and/or windows.