Page 70 - Pipeline Rules of Thumb Handbook

P. 70

Construction 57

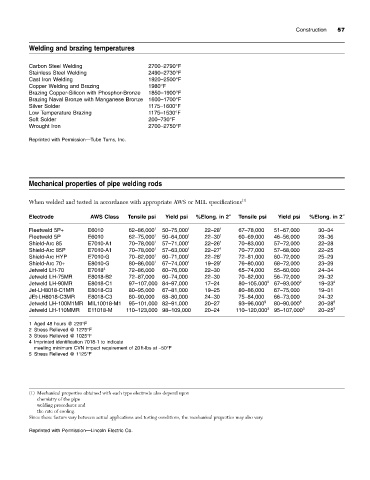

Welding and brazing temperatures

Carbon Steel Welding 2700–2790°F

Stainless Steel Welding 2490–2730°F

Cast Iron Welding 1920–2500°F

Copper Welding and Brazing 1980°F

Brazing Copper-Silicon with Phosphor-Bronze 1850–1900°F

Brazing Naval Bronze with Manganese Bronze 1600–1700°F

Silver Solder 1175–1600°F

Low Temperature Brazing 1175–1530°F

Soft Solder 200–730°F

Wrought Iron 2700–2750°F

Reprinted with Permission—Tube Turns, Inc.

Mechanical properties of pipe welding rods

When welded and tested in accordance with appropriate AWS or MIL specifications (1)

Electrode AWS Class Tensile psi Yield psi %Elong. in 2≤ Tensile psi Yield psi %Elong. in 2≤

Fleetweld 5P+ E6010 62–86,000 1 50–75,000 1 22–28 1 67–78,000 51–67,000 30–34

Fleetweld 5P E6010 62–75,000 1 50–64,000 1 22–30 1 60–69,000 46–56,000 28–36

Shield-Arc 85 E7010-A1 70–78,000 1 57–71,000 1 22–26 1 70–83,000 57–72,000 22–28

Shield-Arc 85P E7010-A1 70–78,000 1 57–63,000 1 22–27 1 70–77,000 57–68,000 22–25

Shield-Arc HYP E7010-G 70–82,000 1 60–71,000 1 22–28 1 72–81,000 60–72,000 25–29

Shield-Arc 70+ E8010-G 80–86,000 1 67–74,000 1 19–29 1 76–80,000 68–72,000 23–29

Jetweld LH-70 E7018 4 72–86,000 60–76,000 22–30 65–74,000 55–60,000 24–34

Jetweld LH-75MR E8018-B2 72–87,000 60–74,000 22–30 70–82,000 56–72,000 29–32

Jetweld LH-90MR E8018-C1 97–107,000 84–97,000 17–24 80–105,000 2 67–93,000 2 19–23 2

Jet-LH8018-C1MR E8018-C3 80–95,000 67–81,000 19–25 80–86,000 67–75,000 19–31

JEt-LH8018-C3MR E8018-C3 80–90,000 68–80,000 24–30 75–84,000 66–73,000 24–32

Jetweld LH-100M1MR MIL10018-M1 95–101,000 82–91,000 20–27 93–96,000 5 80–90,000 5 20–28 5

Jetweld LH-110MMR E11018-M 110–123,000 98–109,000 20–24 110–120,000 3 95–107,000 3 20–25 3

1 Aged 48 hours @ 220°F

2 Stress Relieved @ 1275°F

3 Stress Relieved @ 1025°F

4 Imprinted identification 7018-1 to indicate

meeting minimum CVN impact requirement of 20 ft-lbs at -50°F

5 Stress Relieved @ 1125°F

(1) Mechanical properties obtained with each type electrode also depend upon

chemistry of the pipe

welding procedures and

the rate of cooling.

Since these factors vary between actual applications and testing conditions, the mechanical properties may also vary.

Reprinted with Permission—Lincoln Electric Co.