Page 65 - Pipeline Rules of Thumb Handbook

P. 65

52 Pipeline Rules of Thumb Handbook

positive and the tangent ahead is greater positive slope, a sag

is noted. The reverse holds true for change in negative slope:

if the tangent ahead is increasing, the transition is an over-

bend; if it is decreasing, the transition is a sag. The unlike

algebraic signs are added and like signs are subtracted. Figure

2, station 2 + 00, shows a positive 10° slope approaching the

overbend and a negative 1° slope leaving it. Since the signs

are unlike, the sum of the two angles is 11° and since the slope

is positive and decreasing, the notation overbend is used.

Side bend angles

Side bends are determined by “eyeballing” a P.I. in the

ditch and setting the instrument up over it. A back sight is

taken on the ditch or preceding P.I., whichever is more easily

read. The scope is flipped and a foresight is taken on the ditch

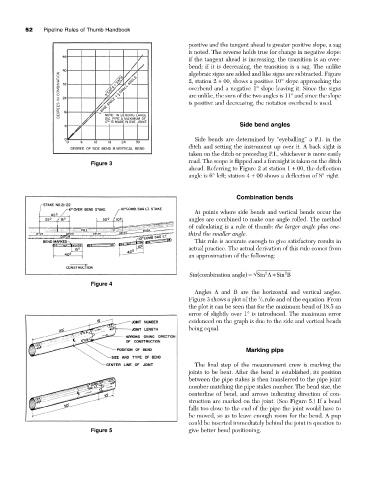

Figure 3

ahead. Referring to Figure 2 at station 1 + 00, the deflection

angle is 6° left; station 4 + 00 shows a deflection of 8° right.

Combination bends

At points where side bends and vertical bends occur the

angles are combined to make one angle rolled. The method

of calculating is a rule of thumb: the larger angle plus one-

third the smaller angle.

This rule is accurate enough to give satisfactory results in

actual practice. The actual derivation of this rule comes from

an approximation of the following:

(

2

2

+

Sin combination angle) = Sin A Sin B

Figure 4

Angles A and B are the horizontal and vertical angles.

1

Figure 3 shows a plot of the / 3 rule and of the equation. From

the plot it can be seen that for the maximum bend of 18.5 an

error of slightly over 1° is introduced. The maximum error

evidenced on the graph is due to the side and vertical bends

being equal.

Marking pipe

The final step of the measurement crew is marking the

joints to be bent. After the bend is established, its position

between the pipe stakes is then transferred to the pipe joint

number matching the pipe stakes number. The bend size, the

centerline of bend, and arrows indicating direction of con-

struction are marked on the joint. (See Figure 5.) If a bend

falls too close to the end of the pipe the joint would have to

be moved, so as to leave enough room for the bend. A pup

could be inserted immediately behind the joint in question to

Figure 5 give better bend positioning.