Page 87 - Pipeline Rules of Thumb Handbook

P. 87

74 Pipeline Rules of Thumb Handbook

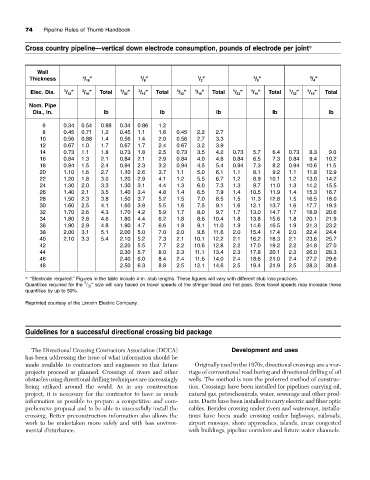

Cross country pipeline—vertical down electrode consumption, pounds of electrode per joint*

Wall

Thickness 5 / 16 ≤ 3 / 8 ≤ 1 / 2 ≤ 5 / 8 ≤ 3 / 4 ≤

Elec. Dia. 5 / 32 ≤ 3 / 16 ≤ Total 5 / 32 ≤ 3 / 16 ≤ Total 5 / 32 ≤ 3 / 16 ≤ Total 5 / 32 ≤ 3 / 16 ≤ Total 5 / 32 ≤ 3 / 16 ≤ Total

Nom. Pipe

Dia., in. lb lb lb lb lb

6 0.34 0.54 0.88 0.34 0.86 1.2

8 0.45 0.71 1.2 0.45 1.1 1.6 0.45 2.2 2.7

10 0.56 0.88 1.4 0.56 1.4 2.0 0.56 2.7 3.3

12 0.67 1.0 1.7 0.67 1.7 2.4 0.67 3.2 3.9

14 0.73 1.1 1.8 0.73 1.8 2.5 0.73 3.5 4.2 0.73 5.7 6.4 0.73 8.3 9.0

16 0.84 1.3 2.1 0.84 2.1 2.9 0.84 4.0 4.8 0.84 6.5 7.3 0.84 9.4 10.2

18 0.94 1.5 2.4 0.94 2.3 3.2 0.94 4.5 5.4 0.94 7.3 8.2 0.94 10.6 11.5

20 1.10 1.6 2.7 1.10 2.6 3.7 1.1 5.0 6.1 1.1 8.1 9.2 1.1 11.8 12.9

22 1.20 1.8 3.0 1.20 2.9 4.1 1.2 5.5 6.7 1.2 8.9 10.1 1.2 13.0 14.2

24 1.30 2.0 3.3 1.30 3.1 4.4 1.3 6.0 7.3 1.3 9.7 11.0 1.3 14.2 15.5

26 1.40 2.1 3.5 1.40 3.4 4.8 1.4 6.5 7.9 1.4 10.5 11.9 1.4 15.3 16.7

28 1.50 2.3 3.8 1.50 3.7 5.2 1.5 7.0 8.5 1.5 11.3 12.8 1.5 16.5 18.0

30 1.60 2.5 4.1 1.60 3.9 5.5 1.6 7.5 9.1 1.6 12.1 13.7 1.6 17.7 19.3

32 1.70 2.6 4.3 1.70 4.2 5.9 1.7 8.0 9.7 1.7 13.0 14.7 1.7 18.9 20.6

34 1.80 2.8 4.6 1.80 4.4 6.2 1.8 8.6 10.4 1.8 13.8 15.6 1.8 20.1 21.9

36 1.90 2.9 4.8 1.90 4.7 6.6 1.9 9.1 11.0 1.9 14.6 16.5 1.9 21.3 23.2

38 2.00 3.1 5.1 2.00 5.0 7.0 2.0 9.6 11.6 2.0 15.4 17.4 2.0 22.4 24.4

40 2.10 3.3 5.4 2.10 5.2 7.3 2.1 10.1 12.2 2.1 16.2 18.3 2.1 23.6 25.7

42 2.20 5.5 7.7 2.2 10.6 12.8 2.2 17.0 19.2 2.2 24.8 27.0

44 2.30 5.7 8.0 2.3 11.1 13.4 2.3 17.8 20.1 2.3 26.0 28.3

46 2.40 6.0 8.4 2.4 11.6 14.0 2.4 18.6 21.0 2.4 27.2 29.6

48 2.50 6.3 8.8 2.5 12.1 14.6 2.5 19.4 21.9 2.5 28.3 30.8

* “Electrode required.” Figures in the table include 4-in. stub lengths. These figures will vary with different stub loss practices.

5

Quantities required for the / 32 ≤ size will vary based on travel speeds of the stringer bead and hot pass. Slow travel speeds may increase these

quantities by up to 50%.

Reprinted courtesy of the Lincoln Electric Company.

Guidelines for a successful directional crossing bid package

The Directional Crossing Contractors Association (DCCA) Development and uses

has been addressing the issue of what information should be

made available to contractors and engineers so that future Originally used in the 1970s, directional crossings are a mar-

projects proceed as planned. Crossings of rivers and other riage of conventional road boring and directional drilling of oil

obstacles using directional drilling techniques are increasingly wells. The method is now the preferred method of construc-

being utilized around the world. As in any construction tion. Crossings have been installed for pipelines carrying oil,

project, it is necessary for the contractor to have as much natural gas, petrochemicals, water, sewerage and other prod-

information as possible to prepare a competitive and com- ucts. Ducts have been installed to carry electric and fiber optic

prehensive proposal and to be able to successfully install the cables. Besides crossing under rivers and waterways, installa-

crossing. Better preconstruction information also allows the tions have been made crossing under highways, railroads,

work to be undertaken more safely and with less environ- airport runways, shore approaches, islands, areas congested

mental disturbance. with buildings, pipeline corridors and future water channels.